Custom 2K Plastic Injection Molding Parts

Design Versatility: Combining different materials or colors within one part offers greater design versatility when creating complex and functional components.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware, Daily Commodity |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Mobile |

| Certification | TS16949, CE, ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | Negotiated |

| Number of Holes | 1 |

| Brand | YCH Mold |

| Package | Wooden Case Package According to Customers’ Requirements |

| Price Term | Fob CFR CIF Dat DDP EXW |

| Mould Life | 100-5000K Shots |

| QC Machine | 3D Measurement, Profile Projector |

| Mould Material | S136/2344/718/738/Nak80/P20 etc. |

| Mould Standards | Dme, Hasco, Fvtaba, Lkm and So on |

| Tool Machine | CNC, CNC-Wirecut, E.D.M, Milling, Grinding |

| Export Country | All Over The World |

| Transport Package | Plywood Case |

| Specification | According Client’s Drawing or Sample |

| Origin | Shenzhen China |

| HS Code | 8480710090 |

| Production Capacity | 60 Sets / Month |

Product Features

Custom 2K (two-shot) double shot plastic injection molding parts feature several unique characteristics that set us apart:

1.Design Versatility: Combining different materials or colors within one part offers greater design versatility when creating complex and functional components.

2.Improved Durability: Two-shot molding can combine materials of differing properties for parts with improved durability and performance, creating parts with enhanced longevity and functionality.

3.Enhanced Aesthetics: Through this process, multiple colors or materials may be combined together in order to increase visual appeal of the final product.

4.Reduced Assembly Requirements: By integrating multiple materials or colors together in one process, assembly steps may often be reduced significantly and costs reduced along with improved efficiency. This results in cost savings as well as greater effectiveness of assembly operations.

5.Seamless Bonding: Two-shot molding provides an seamless bond between different materials, leading to stronger, more reliable parts.

6.Complex Geometries: This technique facilitates the production of complex part geometries that might otherwise be difficult to make with traditional molding methods.

By emphasizing these characteristics, YCH Mold can leverage the advantages of 2K double shot plastic injection molding to produce custom parts tailored specifically for applications across many different fields.

Mold features:

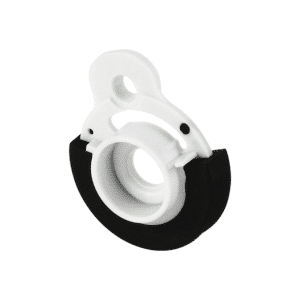

- Toy Industry Wheel part.

- Dual- material injection mold/double injection mold/ 2 shot mold/2k injection moulding technology/ two-color mould.

Part function: Component for Baby Car Toy Industry

Part material: PP+TPU