Project Management

- Selection Techniques for Plastic Mold Materials

- Basic Knowledge Of Injection Molding Process

- Differences Between Two Plate Molds, Three Plate Molds, And Hot Runner Molds

- Common Equipment For Plastic Injection Mold Tooling

- Standard Trial Process For Injection Molds

- Five Molding Processes For Injection Molding

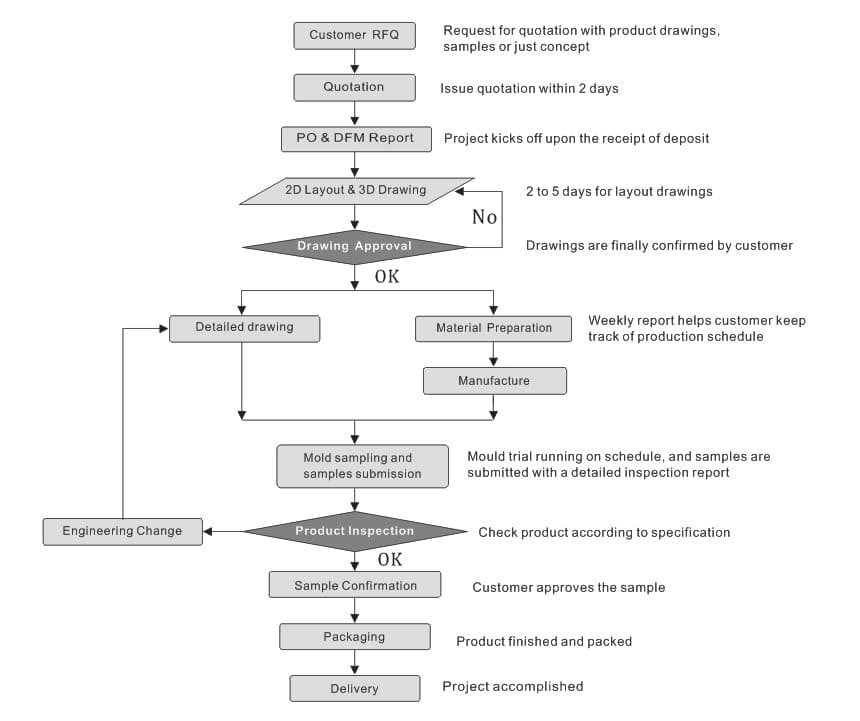

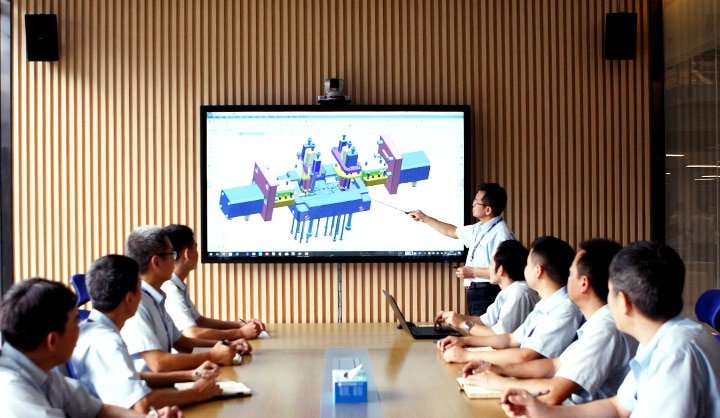

In order to offer customers the molds and products with good quality and better lead time, we set up the project management process.

After new project input, project manager with project engineer will get involve in the project process, work with engineering team to provide customer DFM report, Mold Design.

YCHMOLD’s custom plastic mold service is a service providing on-demand prototype and production molding. We take a customer-first approach which means we find the right injection molding supplier within our manufacturing supplier network to mold the parts the way you need them—without design compromises—at the right price point. We offer expert consultation on each injection mold quote and project managers on every order to move your parts from design to production. Our team has experience in every industry, especially medical injection molding and automatic injection molding.

During manufacturing period, we will keep customer updated with weekly report contains detailed pictures, after T1, mold trial report and samples dimensional report will be supplied. For mold trials and final trial before mold shipping, engineers will check the mold according to checklists to ensure mold can run well at customer’s side after mold shipping.

Project Management Plays an Important Role in Industry

Plastic injection molding is a highly competitive industry requiring precision, efficiency, and strict timeline adherence; thus making effective project management essential to its success. An organized approach must therefore be put in place.

Project management plays an integral part in ensuring projects run seamlessly from start to finish, providing a framework for planning, organizing and controlling every element of a project. When implemented properly by companies they can optimize resource allocation while minimising risks while cutting costs as well as enhance overall productivity.

Project management plays an essential role in facilitating clear communication among team members. By opening lines of communication across departments and encouraging teamwork among them, potential issues can be quickly and effectively resolved.

Effective project management also enables businesses to set realistic expectations with their clients by thoroughly understanding each project’s scope upfront and matching it against resources and capabilities available to them.

Companies should strive to deliver client expectations more fully rather than overpromising or underdelivering.

Key Elements of Effective Project Management

Effective project management in plastic injection molding is crucial, ensuring projects are completed on schedule, under budget and to desired quality standards. To reach such levels of success there are multiple key elements which should be kept in mind:

Understanding and setting realistic expectations are vital aspects of project planning, with this including clearly outlining its objectives, deliverables, as well as any restrictions or constraints associated with its goals and any constraints or limits it might face. By having an in-depth knowledge of both what must be accomplished as well as available resources you can set reasonable goals for yourself and your team.

Timelines and risk assessments are vital parts of effective project management. A timeline enables better planning and coordination by setting deadlines for each phase, and by identifying potential threats early, proactive solutions can be found before they become major problems.

Communication and collaboration among project team members cannot be overemphasized. An open channel of dialogue ensures everyone stays up-to-date about progress, challenges and changes of direction; collaboration ensures all parties involved participate actively in decision making processes.

Quality control measures at every stage of a project are vital in upholding high standards. Regular inspections and tests help detect any flaws or deviations early so they can be quickly addressed by project team.

Implementing continuous improvement strategies into your project management approach will drive innovation and efficiency, encouraging feedback from team members on mistakes made while searching for ways to enhance processes going forward.

Implementing these key components throughout all stages – from conception through production – plastic injection molding companies can confidently navigate success!

Preparing a Timeline and Recognizing Potential Risks

As part of any successful plastic injection molding project, having an accessible timeline is of utmost importance. A timeline offers structure to keep teams focused on meeting deadlines; but not simply setting random dates; rather it means understanding each task’s complexities and allocating time accordingly.

First step to creating an efficient timeline: break your project down into smaller, manageable tasks to better estimate their completion times and identify any dependencies between them.

Once your tasks have been defined, it’s essential to assess any risks that might disrupt their timeline. Such threats might include machine malfunctions or shortages in materials or even changes in customer requirements that necessitate changes to schedules or requirements. By anticipating such potential hiccups early, contingency plans or extra time buffers can be created to lessen their effects and mitigate impacts when they do arise.

Communication among your team members is also of utmost importance during this process, so that all are aware of their responsibilities and the significance of adhering to timeline. By maintaining open lines of dialogue you can address any problems or obstacles as soon as they arise.

At every point in a project, external stakeholders such as customers, suppliers, or anyone with an interest should also be kept up to date about its progress and any concerns that arise proactively to maintain trust between all involved and ensure successful project outcomes for everyone. Sharing progress updates or responding quickly to concerns helps maintain that alignment as all remain focused towards reaching success together.

Making an accurate timeline requires considering all relevant aspects, while anticipating any possible risks to prepare yourself for potential setbacks along the way.

Communication and Collaboration within the Project Team

Effective project management in plastic injection molding industry relies heavily on effective communication and collaboration among team members in order to reach successful outcomes. All team members must maintain open lines of communication while cooperating effectively towards reaching goals.

Communication within any project team requires ongoing updates and status reports that inform everyone involved of progress being made, any roadblocks encountered and changes needed for implementation. By keeping everyone aware, issues can be quickly addressed while solutions found more efficiently.

Collaboration is also vital to project success, providing team members the chance to leverage individual strengths and expertise together in order to overcome any hurdles or achieve desired goals. Collaboration fosters creativity, innovation and problem-solving abilities within team members.

Effective communication and collaboration rely on active listening from each member, so everyone should feel heard during discussions or meetings. Not only does this foster trust but it encourages diverse perspectives which ultimately leads to more informed decision-making processes.

Technology tools such as project management software or platforms for document sharing facilitate real-time collaboration even among geographically dispersed teams, providing seamless information exchange. These tools ensure stakeholders get what they need regardless of physical distance between locations.

Ensuring strong communication channels within a project team increases efficiency while decreasing miscommunication or errors due to lack of clear direction or poor coordination.

Conclusion:

Effective project management in plastic injection molding is crucial. It ensures projects are delivered on time, on budget, and uphold desired quality standards. By clearly outlining project objectives and setting realistic expectations before creating timelines and identifying any risks early, companies can navigate complex endeavors more effortlessly.

Communication and collaboration play an essential part in successful project management. Regular engagement between team members helps foster transparency and ensures everyone is on the same page, leading to more efficient problem-solving while decreasing delays or miscommunication.

Quality control measures should be implemented at every stage of a project – from material selection through production processes and final inspection – in order to guarantee customer satisfaction while also preventing costly rework or recalls.

Utilizing continuous improvement strategies allows companies to stay ahead of competition by finding ways to increase efficiency, cut waste and boost performance on an ongoing basis.