Custom Unscrewing Flip Top Mould with Shampoo Cap

Our mold is designed and produced according to relevant industry standards and regulations regarding production of packaging materials, guaranteeing product safety, hygiene standards and regulatory compliance in consumer goods applications.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

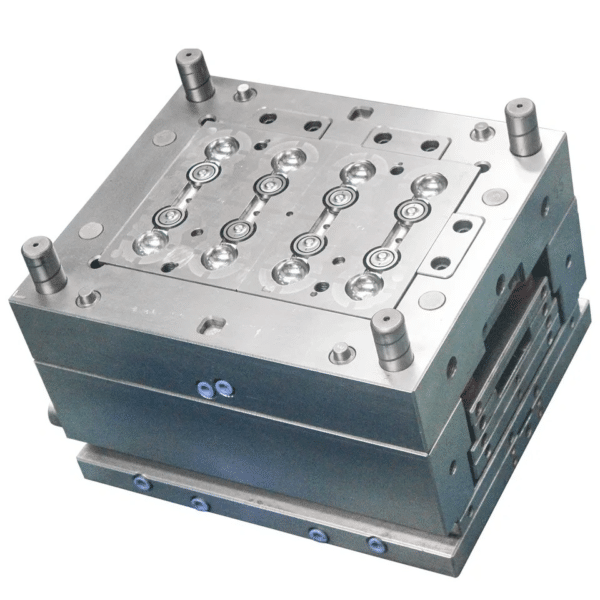

| Model NO. | YCHUM-20230689 |

| Plastic Material | HDPE |

| Process Combination Type | Progressive Die |

| Application | Household Appliances |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Standard | HASCO |

| Customized | Yes |

| Name | Plastic Flip Top Cap Mould |

| Mould Material | 45#, P20, 718, 2738, Nak80, S136 etc. |

| Mould Base | Lkm, Hasco, Dme |

| No,Cavity | Single or Multi |

| Mould Life | Above300, 000 Times |

| Equipment | CNC, Nc EDM, Wire-Cutting, Large-Scale… |

| Transport Package | Wooden Case |

| Specification | to meet customer needs |

| Trademark | YS |

| Origin | Shenzhen China |

| HS Code | 8480719025 |

| Production Capacity | 25 Plastic Flip Top Cap Mould Per Month |

Product Features

Here are a few features of our custom unscrewing flip-top mold for manufacturing shampoo caps:

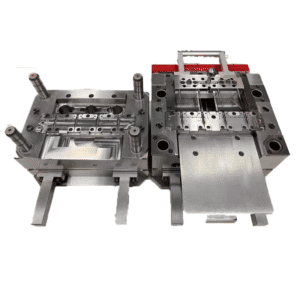

1.Precision Unscrewing Mechanism:The mold incorporates a precise unscrewing mechanism for reliable and efficient demolding of flip-top shampoo caps without thread integrity issues and risk to damage.

2.Multi-Cavity Configuration:To maximize production efficiency, molds with multiple-cavity configuration are designed so as to facilitate simultaneous molding of multiple shampoo caps per cycle and increase productivity while decreasing manufacturing costs.

3.Adjustable Ejection System:The mold comes equipped with an adjustable ejection system to facilitate smooth and reliable release of molded parts, accommodating variations in part geometry and material properties to deliver consistent performance with minimum downtime.

4.Customizable Design Options:Our clients enjoy the flexibility to personalize all aspects of a shampoo cap design – shape, size, color and branding elements – for truly customized packaging solutions that resonate with target consumers.

5.High-Quality Materials:Constructed using premium-grade materials like hardened steel or aluminum alloy, our mold is engineered for long-term performance by using materials with superior wear resistance to ensure reliable service over an extended service life span.

6.Integrated Cooling System:An integrated cooling system can help ensure efficient heat dissipation during molding processes, improving cycle times and production downtime while increasing overall productivity.

7.Comprehensive Quality Assurance:Strict quality control measures are implemented throughout the manufacturing process to ensure each shampoo cap satisfies exact dimensional tolerances, functional requirements and aesthetic criteria ensuring consistent quality and performance over time.

8.Compatibility With Injection Molding Machines:The mold can be used with various injection molding machines for seamless integration into existing manufacturing operations and production setups. It offers flexibility and variety.

9.Support and Maintenance Services:The mold manufacturer provides comprehensive support and maintenance services, such as mold installation, training, troubleshooting and preventive maintenance in order to guarantee optimal performance and extend its lifespan.

10.Regulatory Compliance:Our mold is designed and produced according to relevant industry standards and regulations regarding production of packaging materials, guaranteeing product safety, hygiene standards and regulatory compliance in consumer goods applications.