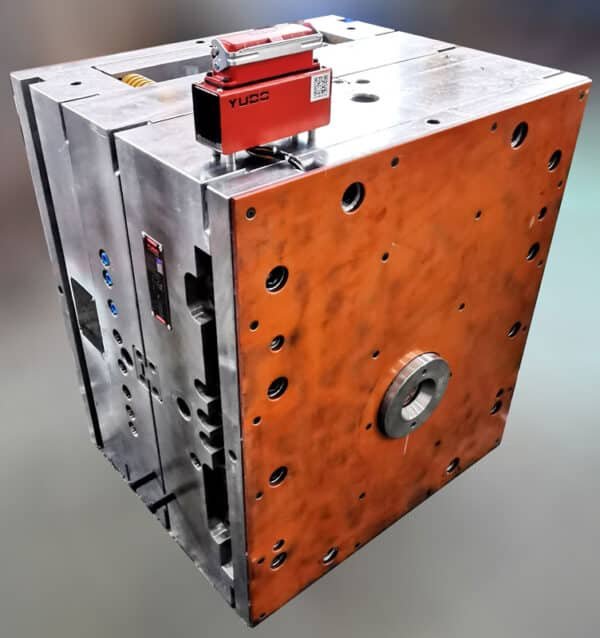

Hot Runner Plastic Injection Mold For Industrial Equipment

Overall, Our Hot Runner Plastic Injection Mold for Industrial Equipment delivers precision control, reduced waste, faster cycle times and the ability to mold complex designs with precision

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Place of Origin | Shenzhen, China |

| Brand Name | YCHMold |

| Model Number | YCH-HRM-20230518 |

| Product | Household Appliance |

| Product Name | Hot Runner Plastic Injection Mold For Industrial Equipment |

| mold material | P20/718/738/NAK80/S136/2738/2316 |

| plastic Material | Acrylic/ABS/PP/PS/PE/PVC/PA6/PA66…..etc |

| Application | Industrial Equipment |

| Mold base | 1050 |

| Surface treatment | Polishing/smooth,texture/frosted, painting, plating, printing |

| Tolerance | 0.003mm-0.01mm |

| Certification | CE RoHS ISO9001 ISO13485 |

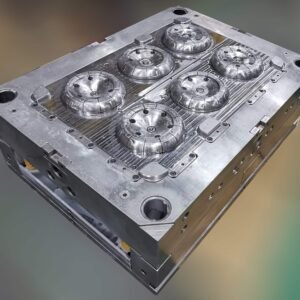

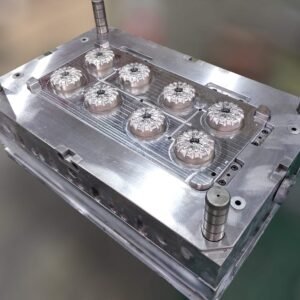

| Mold Cavity | single or multi cavity |

| Mold runner | Hot Runner |

Product Features

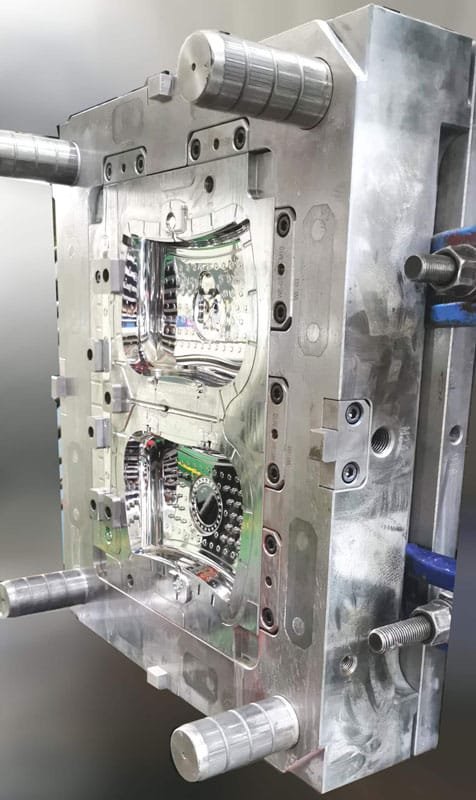

1. Precise Temperature Control: Hot runner systems provide precise temperature control to maintain uniform heating and distribution of molten plastic within mold cavities for improved part quality, decreasing defects while helping achieve consistent part production.

2. Improved Efficiency: Hot runner systems can significantly boost efficiency during injection molding processes by shortening cycle times, decreasing material waste, and streamlining production operations.

3. Design Flexibility: Hot runner molds offer greater design versatility, enabling the creation of complex industrial equipment components with greater precision and accuracy – such as parts with variable wall thickness or intricate geometries.

4. Reduced Gate Marking: Hot runner systems help minimize gate marking, an especially valuable benefit in industrial equipment where aesthetic and surface finish considerations play an essential part. As a result, hot runner systems produce finished parts with reduced cosmetic defects for higher-quality finished parts that meet quality assurance criteria.

5. Material Compatibility: Hot runner plastic injection molds are designed to accommodate an assortment of engineering-grade thermoplastics used in industrial settings, with specific performance needs being accommodated for.