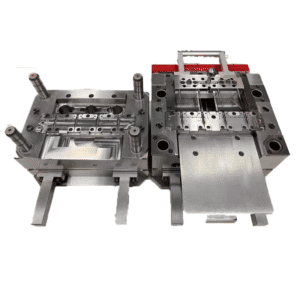

Plastic Unscrewing Insert Pump Molds For Household Appliance

Customization:These molds can be modified to meet any pump design and specification required, meeting specific household appliances’ demands.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Model NO. | YCHUM-20230689 |

| Plastic Material | HDPE |

| Process Combination Type | Progressive Die |

| Application | Household Appliances |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Standard | HASCO |

| Customized | Yes |

| Name | Plastic Flip Top Cap Mould |

| Mould Material | 45#, P20, 718, 2738, Nak80, S136 etc. |

| Mould Base | Lkm, Hasco, Dme |

| No,Cavity | Single or Multi |

| Mould Life | Above 300, 000 Times |

| Equipment | CNC, Nc EDM, Wire-Cutting, Large-Scale… |

| Transport Package | Wooden Case |

| Surface Treatment | Polishing/smooth,texture/frosted, painting, plating, printing , etc. |

| Trademark | YCH Mold |

| Origin | Shenzhen China |

| HS Code | 8480719025 |

| Production Capacity | 25 Plastic Flip Top Cap Mould Per Month |

Product Features

Plastic unscrewing insert pump molds for household appliances boast several key benefits.

1.Threaded Inserts: Molds designed with threaded inserts can make assembly and disassembly of pump components simple and straightforward.

2.Precision Unscrewing Mechanism:Using an unscrewing mechanism allows for accurate removal of threaded components from their mold, guaranteeing accuracy and repeatability in manufacturing processes.

3.Seamless Integration:The design of molds ensures seamless integration of an unscrewing mechanism within their overall mold structures for smooth operation and consistent part quality.

4.Customization:These molds can be modified to meet any pump design and specification required, meeting specific household appliances’ demands.

5.Durability:The combination of high-grade materials and precision machining ensures long-term use in high volume production environments, which makes molds durable enough for continual usage in such settings as factory manufacturing lines.

6.Cost-Effectiveness:These molds make production of household appliance pump components cost-efficient by streamlining molding processes and simplifying assembly, thus cutting overall production expenses.

7. Versatility: These molds have many uses outside household appliances, including automotive, medical and industrial pump applications.