Threaded Pipe Unscrewing Tooling Parts For Water Supply And Drainage System

These product features demonstrate how threaded pipe unscrewing tooling parts can be specifically tailored to meet the unique requirements of water supply and drainage systems, meeting crucial standards such as precision, durability, corrosion resistance and ease of maintenance.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

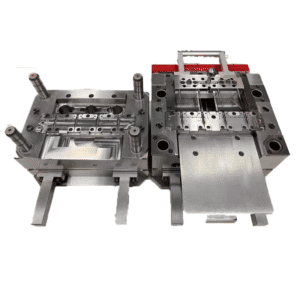

Tool features:

- Inner thread mould/ inner unscrewing mould.

- Outer thread mould/Outer unscrewing mold/ Threaded plasic mouldings.

- Complicated mold structure/ Hydraulic cylinder core pull to form inner thread/ Collapsible core pull .

Part function: Pipes Components for water supply and drainage system

Part material: PP+10%GF natural & black

Shrink rate: .005 inch/inch

Part finish: SPI-B1

Cavity and core steel: H13 (48-52HRC)

Mold base: 1050

Standard components: DME English standard

Gate type: Cold runner sub gate

Number of Cavities.: Single Cavity

Mold size: 450X450X521mm

Injection molding machine: 250 Ton

Product Features

Threaded pipe unscrewing tooling parts designed specifically to unclog water supply and drainage systems feature several useful characteristics, including:

1. Precision Thread Control: Tooling parts have been engineered for precise engagement of threaded pipes to provide secure connections that run leak-free in water supply and drainage applications.

2. Corrosion Resistance: When selecting materials with exceptional corrosion resistance properties for tooling parts, their longevity in water or other harsh environmental environments remains undiminished, contributing to greater system longevity.

3. Easy and Efficient Maintenance: Unscrewing tooling parts have been specifically designed to allow for effortless disassembly and maintenance of threaded pipe connections for quick access within water supply and drainage systems.

4. Compatibility and Versatility: Tooling parts designed specifically to be compatible with various pipe sizes and thread specifications provide greater versatility for their use across different components of water supply and drainage system.

5. Longevity of Construction: Tooling parts designed to withstand mechanical strain and wear associated with repeated industrial usage are engineered for long-term reliability in demanding environments.

These product features demonstrate how threaded pipe unscrewing tooling parts can be specifically tailored to meet the unique requirements of water supply and drainage systems, meeting crucial standards such as precision, durability, corrosion resistance and ease of maintenance.