Mold Design

- Selection Techniques for Plastic Mold Materials

- Basic Knowledge Of Injection Molding Process

- Differences Between Two Plate Molds, Three Plate Molds, And Hot Runner Molds

- Common Equipment For Plastic Injection Mold Tooling

- Standard Trial Process For Injection Molds

- Five Molding Processes For Injection Molding

YCH Mold adheres to a professional philosophy, helps customers optimize product structure, organizes core technical and R&D teams, conducts open communication and review with customers, maintains sufficient communication and exchange, solves customers’ product design problems, and provides new product manufacturing processes and multi- injection molding design concepts, striving to form the best mold design solution, making it easier for customers to occupy the market.

Our experienced designers are capable of creating simple to complex designs and assemblies in 2D and 3D formats.

Suggested improvements on products design for better tooling if necessary

Computer aided mold design

Mold design according to different mold standards (DME, HASCO, etc.)

Capabilities of doing 2D and 3D mold drawings

Existing data exchange formats:

2D Part Drawings (.DWG, .DXF, .PDF)

3D Modeling (.STEP, .STL, .IGES, .X_T, .CATPart)

Design Rules for Injection Molding

Designing injection molding molds involves following several key rules to achieve maximum results and minimize risks and ensure high-quality parts production. By following these regulations, optimal outcomes are assured and mold defects will be reduced significantly and production volumes increased accordingly.

Wall thickness must also be taken into consideration, since an even wall thickness throughout a part can help avoid problems like warping and sink marks. Thick sections may lead to unequal cooling which increases defects while thin ones could create weak points prone to breaking.

One key rule in engineering design is avoiding sharp corners. Sharp corners create stress concentration points which weaken parts and increase risk of cracking or failure, so whenever possible rounded corners should be used not only for their strength but also to ease material flow during injection.

Draft angles must also be factored into mold designs to allow for smooth part ejection from the mold with ease, by providing a slight taper along vertical surfaces. Without draft angles, parts could get caught in the mold or have cosmetic defects due to drag marks on vertical surfaces causing parts to stick therein and remain trapped therein.

Designers must pay particular attention to gate placement. A gate is where molten plastic enters a mold cavity during injection molding and, with careful positioning, can ensure uniform filling and reduce potential weak points within parts.

Undercuts should only be utilized if absolutely necessary as they tend to complicate manufacturing and ejection processes by necessitating additional moving components or mechanisms within a mold.

Adherence to these design rules enables manufacturers to maximize molds for efficient injection molding processes while simultaneously minimizing defects and producing high-quality finished products.

Factors to Keep in Mind when Designing an Injection Mold

Designing an injection mold requires taking into account multiple elements carefully, beginning with material choice for molding process. Different materials have various properties such as flowability and shrinkage rates that could impact design of mold significantly.

Geometry of a part is also an essential consideration. Depending on its shape and size, its design requires particular care in order to produce optimal results; complex geometries may need complex cooling channels or multiple mold pieces while simpler designs might allow for simpler mold construction approaches.

Mold design must also consider production volume. If you plan on manufacturing large volumes of parts, ensure your mold can withstand this high volume without wearing out too quickly; on the other hand, for small batch orders simpler designs might suffice.

Notably, part ejection methods and surface finish requirements must also be carefully taken into account when designing the mold. Will undercuts or side actions need to be included on these parts? How smooth should their finish be? These factors will have an effect not only on how it’s designed but also what additional features or components might be necessary.

Cost plays an essential part in injection mold design. Achieving balance between functionality and affordability when creating your mold involves considering costs such as tooling expenses, maintenance expenses over time and potential savings through efficient manufacturing processes.

By taking into account these elements during your injection mold design process, you can ensure molds that maximize efficiency and effectiveness when producing high-quality parts at scale – saving both time and resources while producing outstanding results!

Best Practices for Creating Efficient and Effective Designs

For successful injection mold designs, there are certain key points you must keep in mind in order to create efficient designs that maximize efficiency and success. Let’s review them now.

Attentive consideration should be paid when choosing the materials for your mold, since different materials have distinctive properties and behaviors during molding processes, so selecting an optimal material choice requires research and consultation with experts in order to arrive at an informed decision.

Underwater mining systems utilise hydraulic fluid as part of their production system to extract metal ores for extraction purposes, giving rise to underground mining operations in South Australia, Australia, New Zealand and beyond. They utilise features that enable easy molding without impacting functionality or quality – factors like simple geometry, reduced undercuts and sufficient draft angles are key considerations here.

Prioritize careful gate design and placement as another best practice. Gate placement plays an integral part in filling patterns as well as mitigating potential defects such as weld lines or air traps, so selecting appropriate gate types (edge gates or sub-gates) that suit part geometry may increase overall efficiency and improve results.

Consideration of cooling system design is also integral for maintaining consistent cycle times and avoiding warping/shrinking issues in manufactured parts. An optimal cooling channel layout must ensure uniform heat distribution within the mold cavity while at the same time optimizing cooling efficiency.

Venting provisions within your mold design help avoid trapped air from creating cosmetic flaws such as surface blemishes or burn marks on finished parts, while proper venting ensures smooth plastic material flow during injection molding processes.

Finally but certainly not least important: always conduct rigorous testing and analysis prior to finalizing your mold design! Utilize computer-aided engineering tools like Moldflow simulation software in order to anticipate potential challenges ahead of time and make necessary modifications accordingly.

By following these best practices for designing efficient and effective injection mold designs, your chances of producing high-quality products while cutting production costs significantly will increase significantly.

Avoid Errors When Designing Injection Molds

As with any design task, injection mold design involves many potential pitfalls which could reduce both its quality and efficiency of final product. By becoming aware of such mistakes early, you can ensure your designs remain accurate and cost effective.

One key misstep to avoid when designing for strength and durability is overlooking wall thickness. An uneven distribution of materials could result in weak spots that lead to part failure; to maximize strength and resilience of designs. Maintaining uniform thickness throughout is vital.

Another mistake can occur by overlooking draft angles. Draft angles ensure smooth ejection from molds; without sufficient draft angles, parts could damage or get stuck during demolding and cause serious setbacks to manufacturing processes.

Misplacement of gates may also wreak havoc with filling and cooling of mold cavities, creating inequitable flow patterns or inadequate cooling that leads to warping or sink marks on finished products.

Poor venting design is another frequent misstep in injection mold design, leading to trapped air inside the cavity that creates voids or burn marks on molded parts. If venting requirements are inadequate, air can buildup can trap inside, potentially creating problems like this one.

Failing to account for shrinkage can result in inaccuracy in final products. Shrinkage occurs as plastic cools down and solidifies within its mold cavity; designers must account for this factor when designing molds.

Staying alert during each stage of injection mold design will allow you to avoid common mistakes and increase productivity for creating superior-grade end products on an ongoing basis.

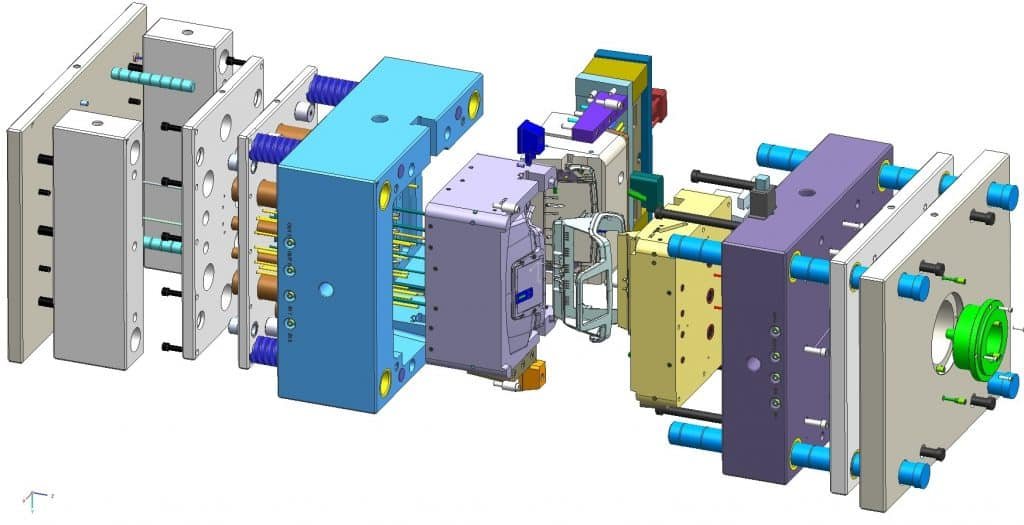

The general process of mold desig

1) Analyze and digest the products and samples.

2) It is necessary to understand whether the customer has any requirements for the specifications of the injection machine in order to determine the range of mold size.

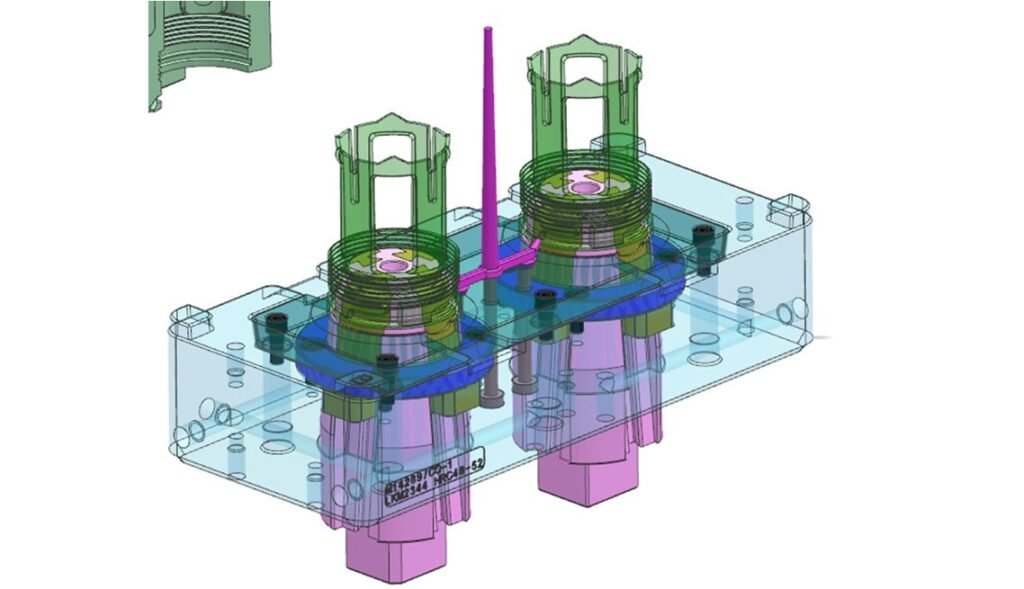

3) Determine the number and arrangement of cavities.

4) Determine the parting surface.

5) If there are rows or diagonal structures, they should be understood first.

6) Pouring system design

7) Determination of inlay structure.

8) Ejection and reset system design.

9) Design of cooling and heating systems.

10) Guiding and positioning devices.

11) Determine the mold and select standard parts.

12) Selection of mold steel.

13) Complete the structural diagram, mold drawing, and cutting.

14) Finally, print out the drawing, verify it, and submit it to the mold design team leader and supervisor.

Staying Current on Industry Trends and Advancements

As an injection mold designer, staying current on industry trends and advances is critical. The field is always changing; new materials, technologies and techniques emerge all of the time – thus staying informed can ensure your designs remain efficient, cost-effective, and competive in today’s marketplace.

Participate actively in industry events like conferences, trade shows and seminars as a means of staying current by networking with experts in your field and learning firsthand about any emerging developments or best practices from experienced professionals. These events also serve as great networking platforms.

Online platforms dedicated to injection mold design are an invaluable way of staying up-to-date on cutting-edge technologies and techniques. There are various websites, forums, and blogs where professionals share their knowledge. Participating in discussions on such platforms will expose you to unique perspectives while keeping you abreast of cutting-edge trends.

Subscribing to industry publications or newsletters can also prove fruitful; these publications usually showcase articles highlighting new advances in materials or processes and may provide case studies that showcase innovative designs or successful projects.

Maintaining up-to-date industry trends requires continued education. Consider enrolling in injection molding design workshops or even seeking advanced degrees if applicable.

Maintaining up-to-date with industry trends helps your designs remain current while maximizing efficiency and effectiveness