1: Milling machines mainly cut workpieces by rotating tools and moving workbenches. Processing range: processing and drilling of some regular parts. Such as roughing of inserts, boxing of small mold templates, some simple runner channels, thimble holes, thimble through holes, screw bottom holes, countersunk holes, small mold water holes, insert water holes, and larger wire-cutting holes in wire cutting. (Due to the development of computer engraving machines, many companies now complete boxing and runner channels with computer engraving machines.)

2: Lathe mainly uses rotating workpieces to simultaneously move the cutting tool for cutting. Processing range: mainly processes some round things. Such as water mouth copper parts, round large inserts, limit posts, support heads, positioning rings, nozzles, threads. (Many complex cross-section round parts are processed by CNC lathes.)

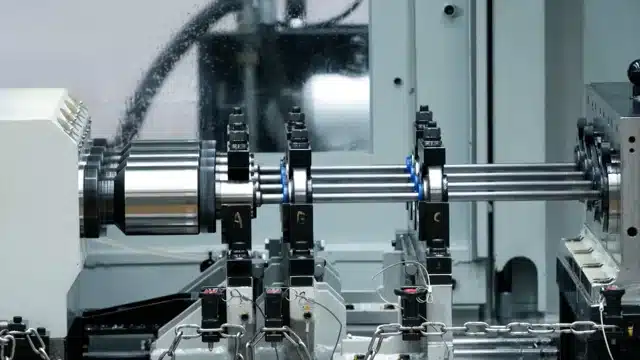

3: Grinder: It mainly cuts workpieces by rotating the grinding wheel and moving the workbench. Processing range: It mainly processes some circular inserts, the processing of the rubber position of the insert pin, flat parting surfaces or inclined surfaces, and some important assembly positions.

Such as wear-resistant blocks, batten, and inclined top mating surfaces. Large water mold mainly grinds some large flat surfaces, or many small pieces arranged together for grinding. The grinder is the most accurate of all processing equipment.

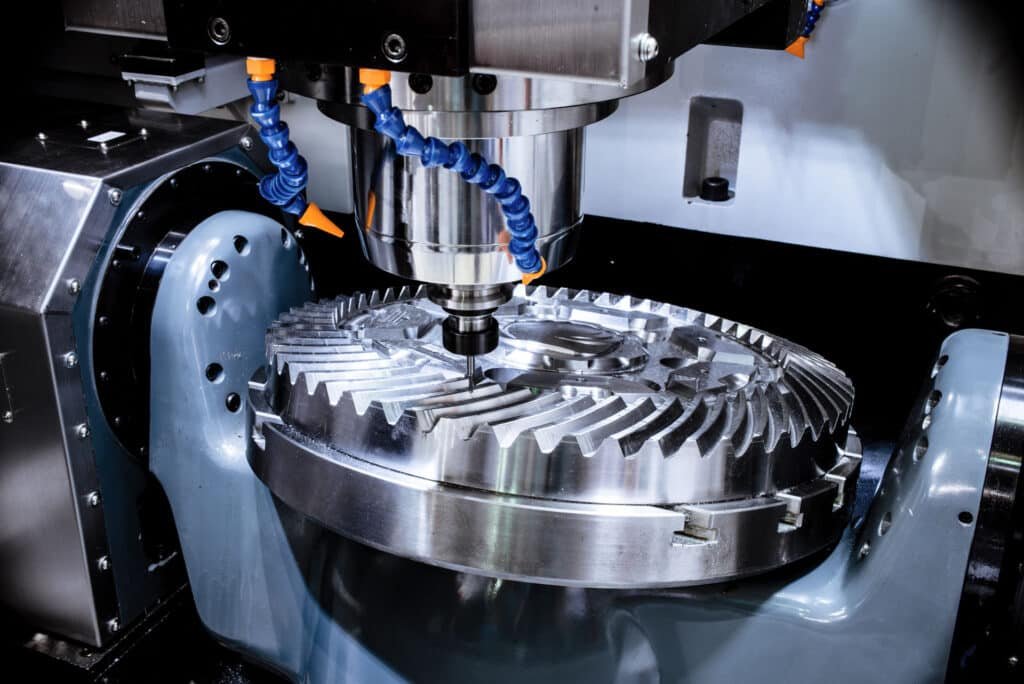

4: CNC mainly cuts workpieces through the rotation of tools and the movement of the workbench. Processing range: mainly used for various complex plane and curved surface processing. It is one of the most widely used CNC machine tools, with three-, four-, and five-axis machines. Common mold core finishing, template frame opening, milling complex curved surface copper male, prototype, etc. Mold processing CNC is divided into ordinary machine, quasi-high speed machine and high speed machine, fine carving machine, gantry milling machine.

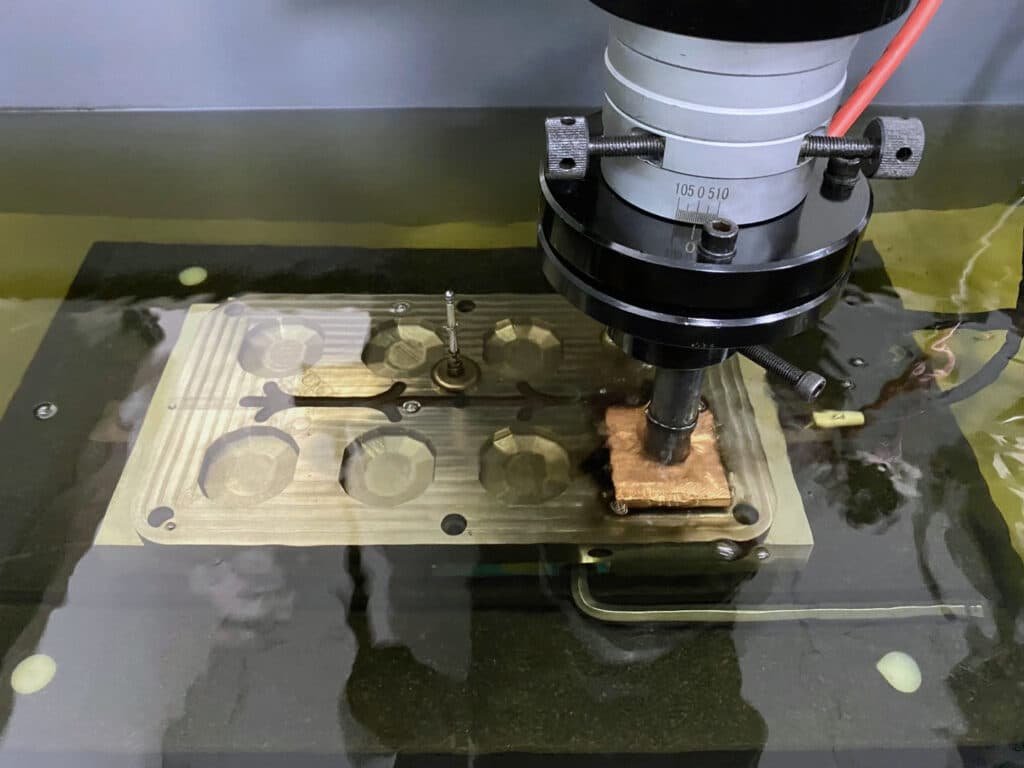

5: Wire cutting mainly uses molybdenum wire as an electrode to cut workpieces. Processing range: used for processing various circular and shaped through-holes, shaped inserts, inserts on the mold core, slanted top holes, thimble insert holes, and through-holes on the mold core. Some shaped copper parts, copper paneling, etc. The common machine tools include fast wire cutting, medium wire cutting, slow wire cutting, and the slower the speed, the higher the accuracy.

The diameter of molybdenum wire is generally 0.08-0.3mm. Due to the influence of molybdenum wire diameter and spark position, a round corner will be formed after wire cutting.

6: The spark machine mainly uses the corrosive effect of the pulse current between the electrode and the workpiece to process the workpiece. The processing range: used to process the positions that cannot be cut by the tool, such as deep bone positions, right angles, and positions that are too deep to be milled. The machine tool is generally divided into ordinary spark machine and mirror spark machine. Its processing speed is directly related to the current size, so the electrode is generally divided into coarse and fine. The coarse spark position is large, generally around 0.2mm. The fine spark position is small, generally around 0.07-0.1mm. Common materials for electrodes include copper and graphite. Copper has a small loss and slow discharge; graphite has a fast discharge, but it has a harmful loss. Compared with copper, graphite has a more beautiful appearance after processing.

7:Deep hole drilling mainly uses the rotation of the drill bit to cut the workpiece. Processing range: mainly processing round holes, such as thimble holes and deep water transport holes. Note that when processing inclined water transport, it is necessary to step on a flat position to process.