2K TPU Double Shot Mold for Audio Accessories PC

These features underscore the advantages of employing 2K molds when manufacturing premium-quality audio accessories with improved functionality, durability, and aesthetics.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

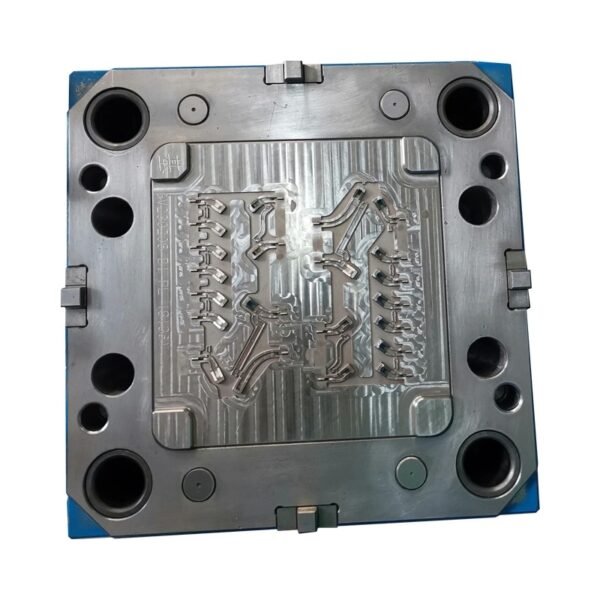

| Model NO. | YCH2K0002 |

| Application | Electronic |

| Runner | Cold Runner |

| Design Software | Pro-E |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 10 Years |

| Mold Steel | S136 |

| Surface Finish | Mirror Polish, Vdi Textu |

| Feed System | Pin Gate |

| Unique | 2K Mold, Soft Plastic Overmolded with Hard Plastic |

| Transport Package | Vacuum+Plywood Wooden Box |

| Specification | 300*400*330 MM |

| Trademark | gv |

| Origin | Shenzhen China |

| HS Code | 84807200 |

| Production Capacity | 200 Sets Per Year |

Product Features

Here are the key product features of our 2K mold designed specifically for audio accessory devices:

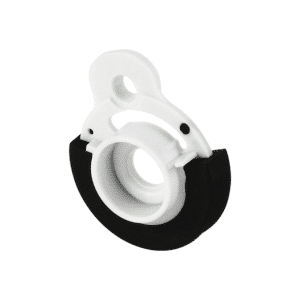

1.Dual Material Compatibility:The 2K Mold facilitates seamless integration of PC and TPU materials for audio accessory production using one manufacturing process, thus creating components with varied properties in just one step.

2.Enhanced Durability:PC provides excellent durability and impact resistance, prolonging the longevity of audio accessories; while TPU provides flexibility and shock absorption that protects delicate electronic components from being damaged in transit.

3.Precision Engineering: Harnessing advanced molding techniques, the 2K mold ensures precise material distribution to enable intricate designs and complex geometries with high levels of accuracy.

4.Multi-Color and Layered Effects:The 2K mold allows users to achieve multicolored or layered effects within one part, increasing aesthetic appeal while providing customizability options for audio accessories.

5.Seamless Integration:The dual-shot molding process unifies PC and TPU materials seamlessly, eliminating assembly steps altogether and producing flawless products without defects or imperfections.

6.Ergonomic Design:TPU’s soft touch properties enhance user comfort, making audio accessories ergonomic and simple to operate during extended use.

7.Environmental Resilience: PC and TPU materials show great environmental resilience against temperature variations and chemical exposure, guaranteeing long-term performance from audio accessories even under challenging conditions.

8.Cost Efficiency: Consolidating multiple manufacturing steps into one step, the 2K mold saves production time, labor costs and material waste – providing an economical option for high volume audio accessory production.

9.High-Quality Finishes:The double shot molding process produces high-quality surface finishes with minimal parting lines or defects, adding visual appeal and increasing perceived value of audio accessories.

10.Compatibility and Versatility: Audio accessory components manufactured using the 2K mold are highly compatible with an array of electronic devices and audio equipment, meeting diverse market requirements and preferences.

These features underscore the advantages of employing 2K molds when manufacturing premium-quality audio accessories with improved functionality, durability, and aesthetics.