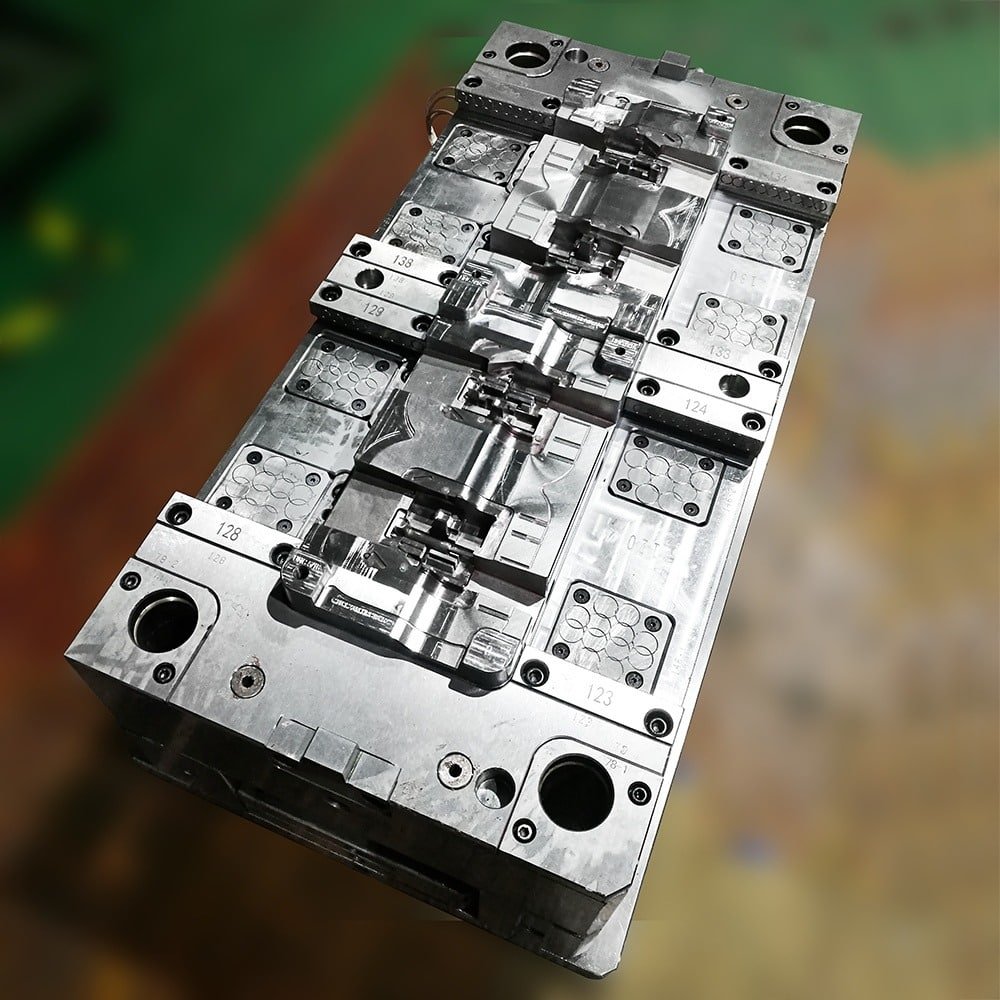

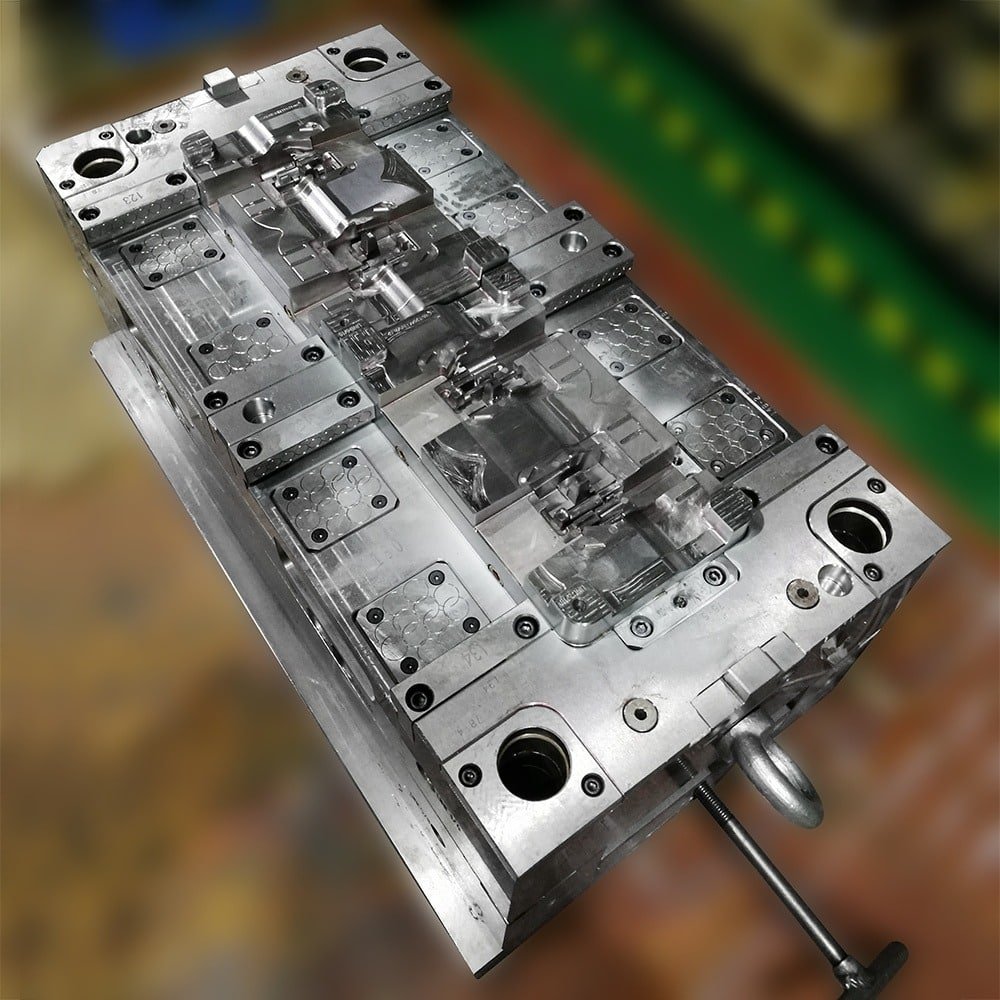

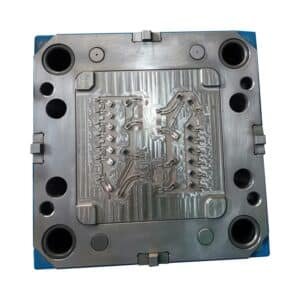

Cold Runner Multi Cavity Plastic Injection Molding Parts For Household Parts

Precision and Consistency: Producing parts with accurate dimensions consistently is critical to ensure high-quality household products.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Model NO. | YCH-2S-0086 |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| Product Shaping Mode | Plastic Injection Mould Ww-007 |

| Mould Base | Lkm, Dme, Hasco etc ; |

| Steel Hardness | 20-60HRC |

| Treatment | Pre-Harden, Nitride, Heat Treatment, Quenching |

| Mould Life | 50K – 1 Million Cycles |

| Product Design Software | Ug, CAD, PRO-E, Solid Works etc |

| Quality | ISO9001:2000 Certified |

| Payment | T/T, Western Union , Money Gram |

| Transport Package | Crate/Pallet |

| Specification | 1000T double injection |

| Trademark | YCH Mold |

| Origin | Shenzhen,China |

| HS Code | 8480719099 |

| Production Capacity | 500 Molds/ Year |

Two color molds, also referred to as 2 shot molds, allow two plastic materials to be simultaneously injected through one injection molding machine and produced once. Often known as double material injection molding, this molding process usually entails multiple molds connected together by special two-color injection molding machinery to complete this task. Nowadays, two-color molding is becoming more and more prevalent on the market and offers benefits like making products look more beautiful while quickly switching colors without spraying paints onto them.

Product Process:

1. Mold Design Control

2. Mold Steel Hardness Inspection

3. Mold Electrodes Inspection

4. Mold Core and Cavity Steel Dimension Inspection

5. Mold Pre-Assembly Inspection

6. Mold Trial Report and Samples Inspection

7. Pre-Shipment Final Inspection

8. Export Product Package Inspection

Product Features

Our cold runner multi-cavity plastic injection molding parts for household products’ product features are as follows:

1. Precision and Consistency: Producing parts with accurate dimensions consistently is critical to ensure high-quality household products.

2. Material Selection: Selecting materials which provide durability, safety, and aesthetic value is of utmost importance when creating household goods.

3. Attractive Finishes: Household parts often demand aesthetic finishes with smooth surfaces and the capability of molding complex shapes, providing added aesthetic value and versatility in everyday use.

4. Efficiency: Manufacturing multiple parts simultaneously using multi-cavity systems helps maximize production efficiency.

5. Strength and Durability: Household parts typically need to meet certain strength and durability criteria in order to withstand daily use, making sure their strength lasts as expected.

6. Cost-Efficient Production: Production should be carried out efficiently while still meeting high quality standards, to keep costs at a minimum and maximise profit potential.