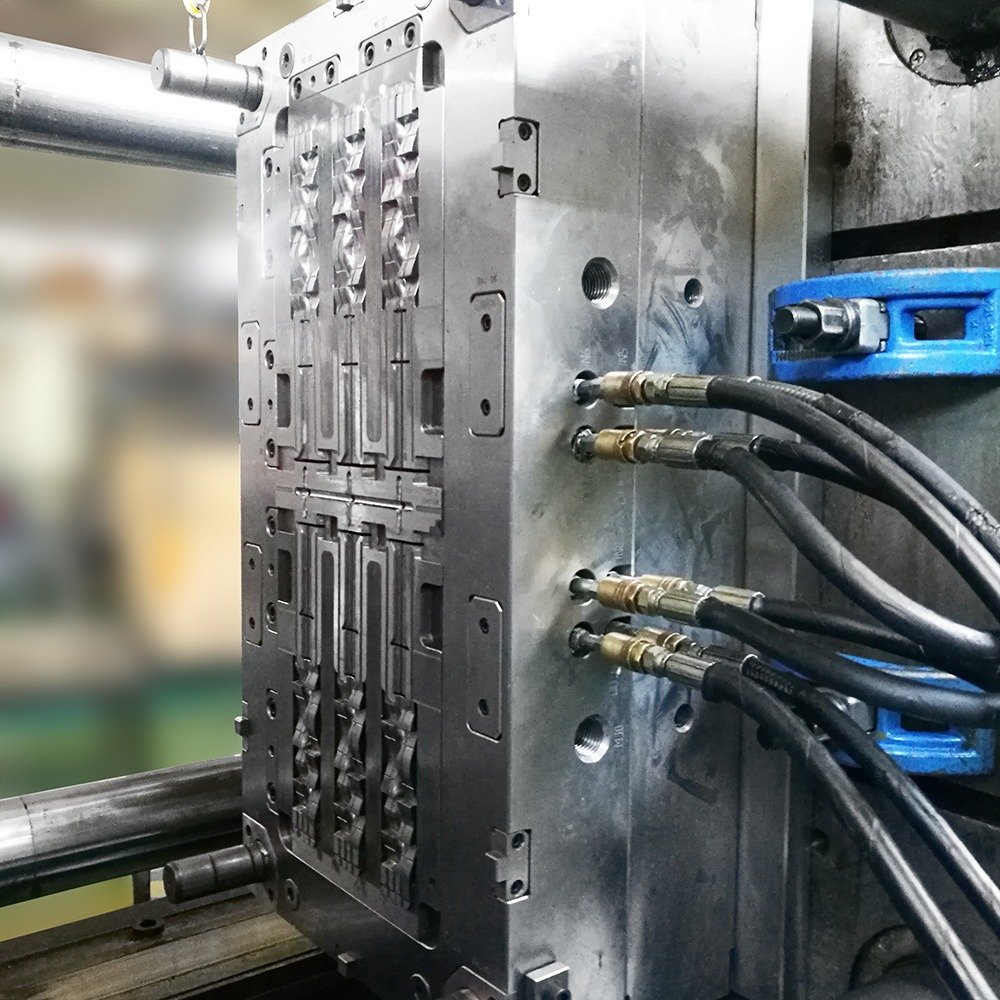

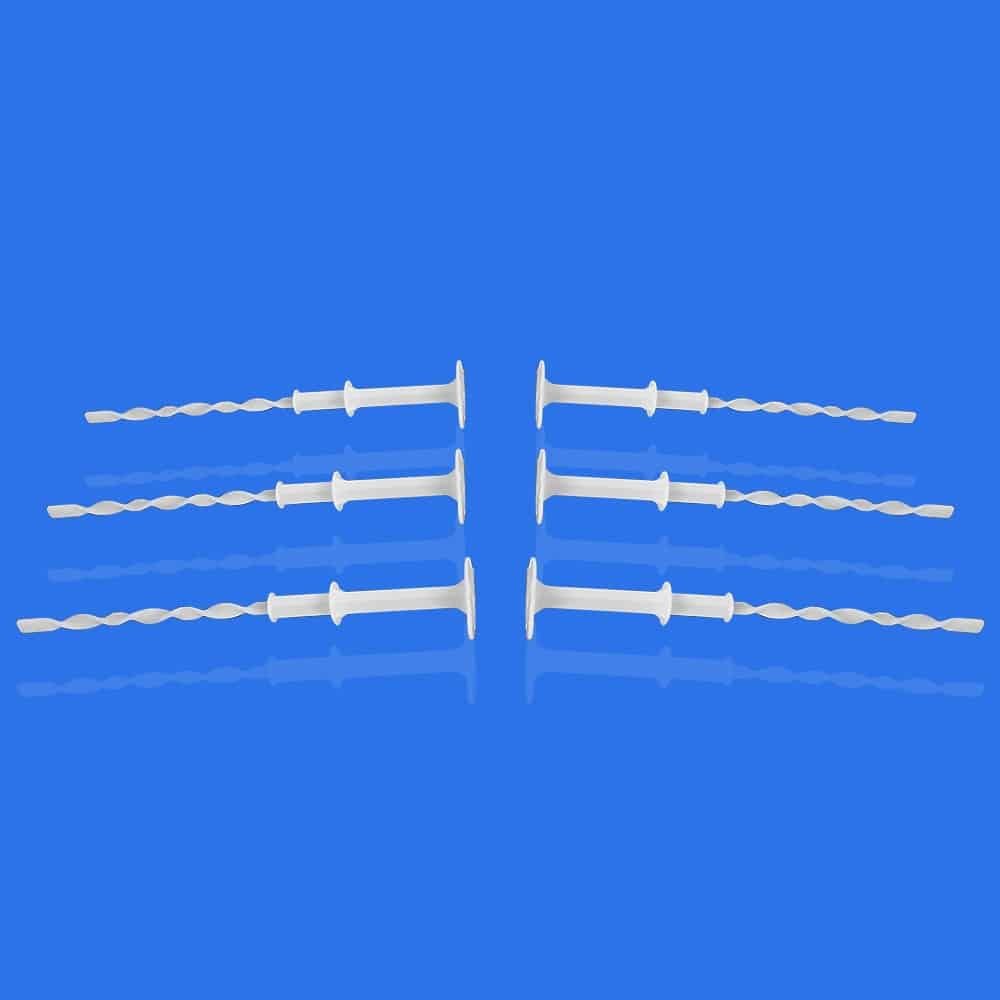

Hot Runner Moulds For Auto Spare Parts

Customizable options to meet specific automotive industry specifications; long-term durability and reliability are features to consider for long-term use.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Main Business | Customization of Injection Molds |

| Selling Point | Quality Assurance |

| Mold Material | Steel |

| Surface Treatment | On customer requirement: |

| Product Material | Plastic |

| Certification | IATF 16949 |

| Experience | 15+ Years of Damper/Latch/Plastic Functional Parts Production 10+ Years of Plastic Injection Molding |

| Lead Time | In general: 45-60 days Special custom service: Making arrangements upon customers’ request |

| Minimum Order | Comply with customer’s demand |

| Packaging | Standard: Pearl cotton and bubble bag, carton box, and seal Large and big quantity: Pallet or as per customers’ requirement |

| Delivery Way | On customer requirement: Express (DHL, FedEx, UPS, EMS, etc.) Standard Delivery (By Sea, By Air, or By Land) |

| Application | Auto Parts, Vehicle, Electronics, Furniture, Home Use and Household Appliances |

Product Features

Here are some key characteristics of our hot runner molds for auto spare parts:

1.Precision engineering to ensure tight tolerances and high-quality part production;

2. Heat control systems to optimize the flow and distribution of molten plastic; production capabilities capable of creating complex designs utilizing various plastic materials;

3.Enhanced productivity with reduced cycle times – these features make us your perfect partner in producing precision parts at competitive costs.

4.Customizable options to meet specific automotive industry specifications; long-term durability and reliability are features to consider for long-term use.