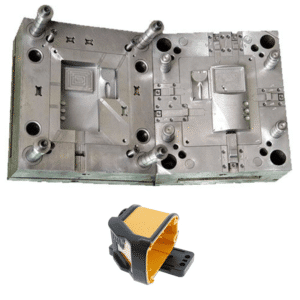

Plastic Overmould Tooling Parts For Electronic tool housing/handler

These product features highlight how plastic overmold tooling parts have been tailored specifically for electronic tool housing/handler products to optimize functionality, durability, ergonomics and aesthetics – meeting key user comfort criteria while protecting components for improved overall performance.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

Tool Features:

- Complicated mold structure/ double injection mould/ dual color molding

- Good cooling and venting

Part function: Electronic tool housing/handle

Mold size: 600*500*361 MM

Injection molding machine size: 250T double injection molding machine

Ejector stroke: 25MM

Part material: PP+30%GF

Shrink rate: .003” inch/inch

Cavity and core steel: GS738H/ 1.2738 (30-32HRC)

Number of cavities.: 1+1 Cavity

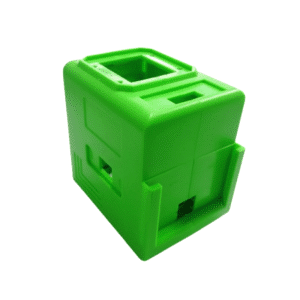

Product Features

Plastic overmold tooling parts designed for electronic tool housing/handler offer several desirable product characteristics, including:

1. Improved Ergonomics: Overmolded tooling parts provide comfortable and ergonomic grips for users, improving handling while decreasing fatigue during extended use of electronic tools.

2. Impact Resistance: Overmolding allows for the incorporation of impact resistant materials that protect delicate electronic components housed within a tool from shocks, providing extra layers of defense from accidental impacts.

3. Vibration Dampening: Tool housing/handler parts designed with overmolded technology can incorporate materials designed to reduce vibration, which results in enhanced stability and user comfort during operations.

4. Customized Aesthetics: Overmolding allows the integration of various colors and textures for enhanced designs that add visual interest to electronic tool housing/handler products.

5. Sealing and Protection: Overmolded parts provide a waterproof shield around internal electronic components to guard them from dust, moisture, or any other environmental factors that might compromise reliability or longevity of electronic tools.

These product features highlight how plastic overmold tooling parts have been tailored specifically for electronic tool housing/handler products to optimize functionality, durability, ergonomics and aesthetics – meeting key user comfort criteria while protecting components for improved overall performance.