Plastic Over Molding Parts For Automotive Industry

These features demonstrate how plastic overmolding for automotive parts addresses critical criteria such as aesthetics, functionality, comfort, durability and simplified assembly in the industry.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

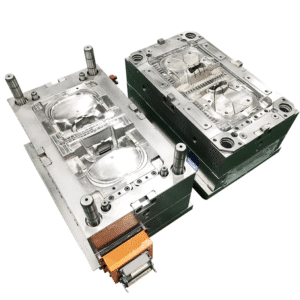

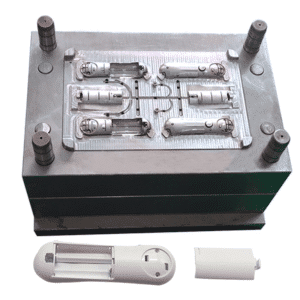

| Cavity Material | 1.2738,1.2343, 1.2344, S7, H13, P20HH, GS738H, LKM738H, 718, 8407, S136, Calmax 635 NAK80, SKD-61,NIMAX, 45#, 50#, Aluminum for prototype mold etc. |

| Runner | Cold runner or Hot runner :YUDO/ HUSKY/MOLD-MASTER/SYNVENTIRE/INCO/ MASTIP/ HASCO/ DME |

| Gate | Submarine gate, tunnel gate, side/edge gate, direct gate, pin point gate, sprue gate, diaphragm gate, fan gate, cashew gate, hook gate, hot tip, hot drop, valve gate etc. |

| Plastic material for parts | PS, SAN, PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE, TPU, TPV etc |

| Process | CNC, high speed carve, EDM ,wiring-cutting, drill, polish etc |

| Lead Time | 10-30 work days depends on the structure and size of products |

| Package | Wooden Case Package or according to customer requirement |

| Price Term | EX Works, FOB Shenzhen, FOB Hong Kong, China, CFR, CIF, DDU, DDP |

Product Features

Our plastic overmolding for automotive parts offers various key benefits tailored to meet the stringent standards set out by this industry, such as:

1. Improved Aesthetics and Ergonomics: Overmolding allows for the incorporation of soft-touch materials or different colors, improving aesthetics and ergonomics on automotive components such as handles, grips and interior trim.

2. Vibration Dampening and Noise Reduction: When combined, automotive parts made with rubberized or elastomeric materials can effectively dampen vibration and noise to enhance driving comfort for vehicle occupants and enhance their experience behind the wheel.

3. Sealing and Weatherproofing: Overmolding provides the opportunity to seal off components using seamless watertight seals that protect them against moisture, dust and environmental elements – this feature makes the technique suitable for exterior as well as under-the-hood applications.

4. Component Integration and Simplified Assembly: Overmolding allows the consolidation of multiple components into a cohesive whole, which simplifies assembly steps while decreasing potential points of failure and overall manufacturing complexity in automotive assemblies.

5. Impact Resistance and Durability: Overmolded parts often demonstrate increased impact resistance and durability, making them suitable for automotive applications that involve extensive mechanical pressure such as exterior trims or protective components that withstand significant mechanical strain such as exterior trims or protective components.

These features demonstrate how plastic overmolding for automotive parts addresses critical criteria such as aesthetics, functionality, comfort, durability and simplified assembly in the industry.