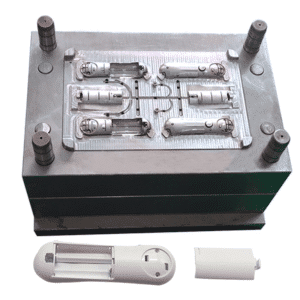

Threaded Unscrewing Plastic Pipe Components For Drainage System

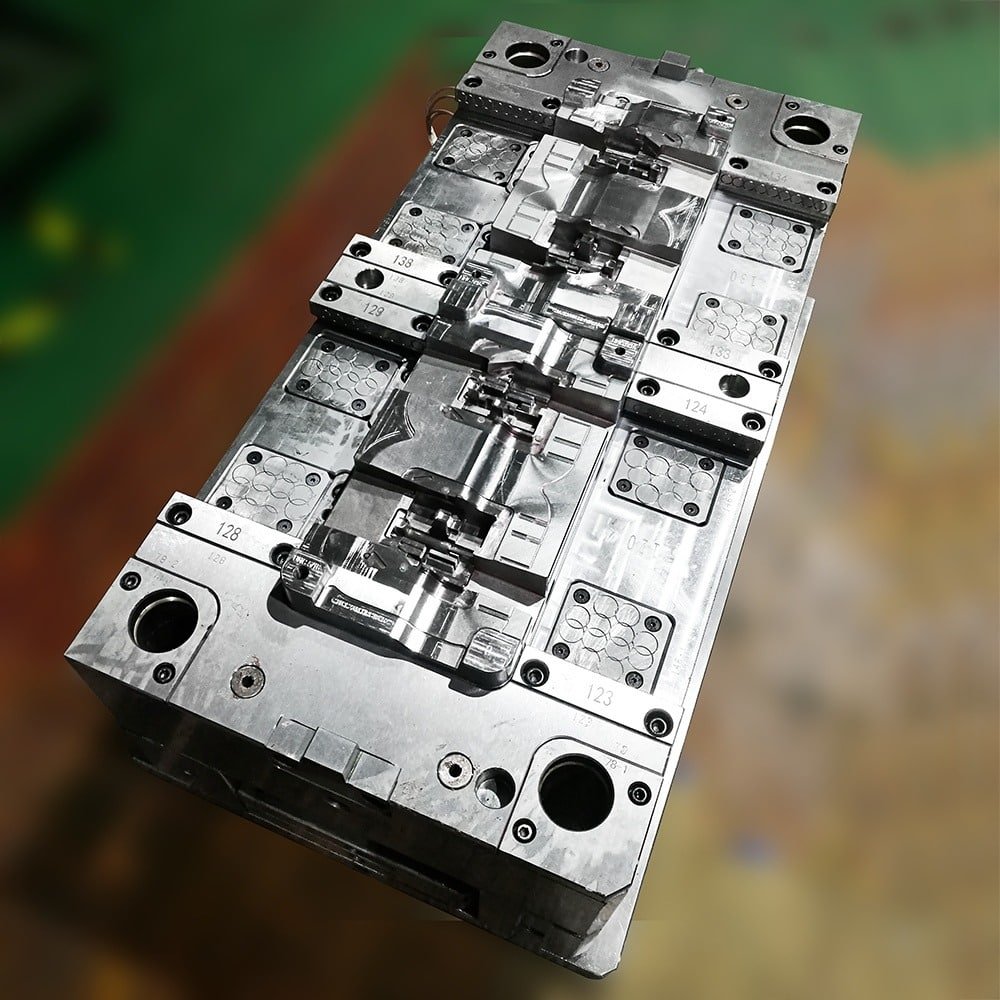

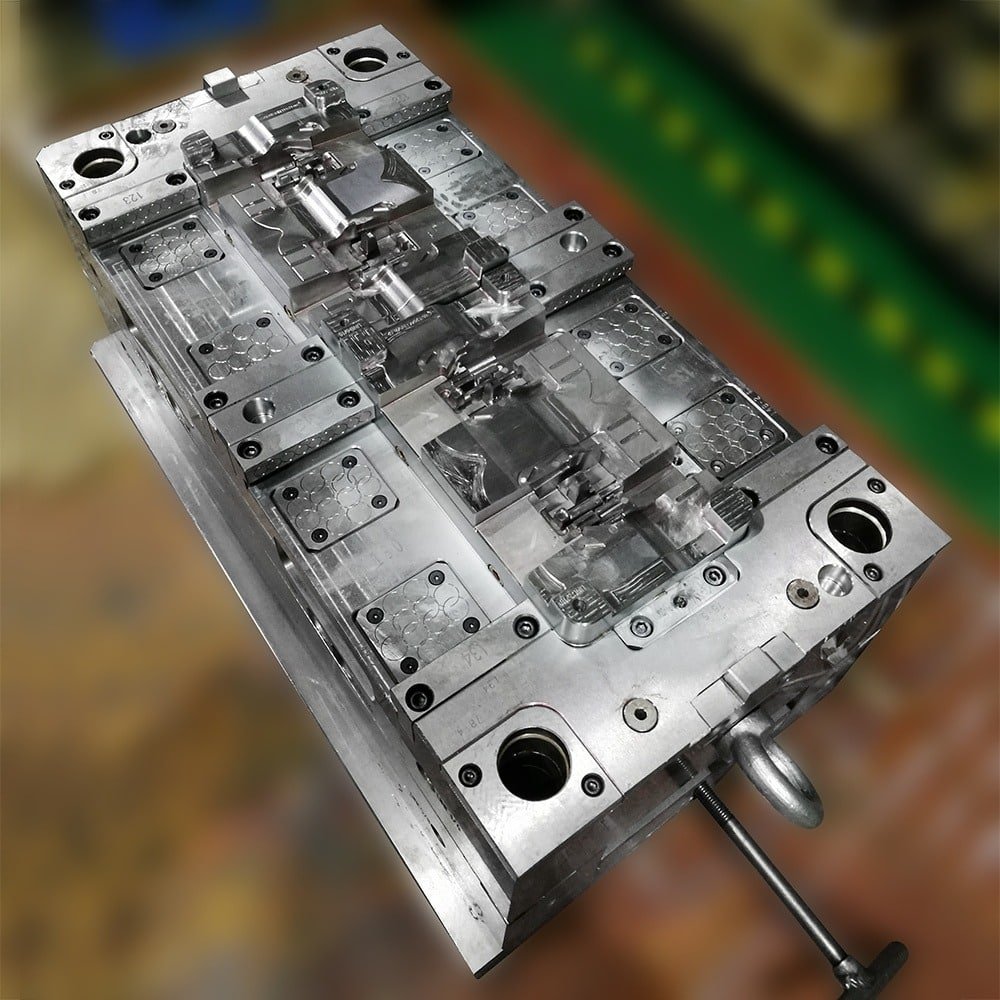

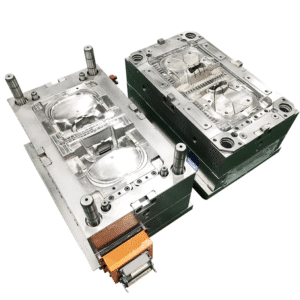

Mold features:

- Inner thread mould/ inner unscrewing mould.

- External thread mould/External unscrewing mold/ Threaded plasic mouldings.

- Complicated mold structure/ Hydraulic cylinder core pull to form inner thread/ Collapsible core pull .

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

Part function: Pipes Components for water supply and drainage system

Mold Size: 550X350X581mm

Part material: PP+10%GF natural

Shrink rate: .005 inch/inch

Cavity and core steel: GS738H (30-32HRC)

Number of Cavities.: Single Cavity

Mold features:

- Inner thread mould/ inner unscrewing mould.

- External thread mould/External unscrewing mold/ Threaded plasic mouldings.

- Complicated mold structure/ Hydraulic cylinder core pull to form inner thread/ Collapsible core pull .

Product Features

Below are the main characteristics of our threaded unscrewing plastic pipe components for drainage systems:

1. Material: These components are often constructed of corrosion-resistant and long-wearing materials such as PVC (polyvinyl chloride) or ABS (acrylonitrile butadiene styrene), to provide durability against harsh environments associated with drainage systems. These durable and corrosion-proof materials ensure long service lives and resistance against harsh weather.

2. Threaded Design: Threaded designs facilitate easy and secure assembly of pipe components. Their threads create an airtight seal between different sections of drainage systems to minimize leaks while providing efficient water flow.

3. Unscrewing Mechanism: The unscrewing feature simplifies maintenance and repair tasks within a drainage system. Components can be quickly disassembled by unscrewing them for cleaning, inspection, or replacing damaged parts if necessary.

4. Compatibility: Threaded unscrewing plastic pipe components are designed to be compatible with standard pipe sizes and fittings used in drainage systems, providing maximum versatility during installations or upgrades of infrastructure or components. This facilitates simple integration with existing infrastructure or components without disrupting their functionality or integration costs.

5. Chemical Resistivity and Corrosion Resistance: Components designed to resist chemicals commonly found in drainage systems such as wastewater treatment agents or cleaning solutions are constructed to resist corrosion over time and help ensure their integrity is preserved over time.

6. Smooth Interior: Pipe components are often designed with smooth interior surfaces to reduce friction and resistance to water flow, helping prevent blockages within drainage systems and ensure efficient operation. This feature can help eliminate potential clogs or blockages.

7. Durability and Longevity: Threaded unscrewing plastic pipe components are built to withstand regular use as well as environmental influences, including UV exposure, temperature fluctuations, mechanical stress and mechanical degrading agents such as mechanical stress. Their UV exposure resistance provides long-term performance reliability.

8. Ease of Installation: These components are often designed with features to facilitate their installation process, including pre-threaded ends and compatibility with tools commonly used by plumbers and installers. This simplifies setup while also helping reduce labor costs and installation times.

Overall, our threaded unscrewing plastic pipe components offer a reliable and efficient drainage system solution; their combination of durability, ease of maintenance and compatibility with standard plumbing practices make them the ideal solution for drainage systems.