The mold industry is a basic industry in manufacturing, the foundation for the transformation of technological achievements, and at the same time an important field of high-tech industries. It is known as the “magnetic industry” that “can turn iron into gold” in industrialized countries such as Europe and the United States.

American industry believes that “the mold industry is the cornerstone of American industry”; Germany believes that it is the “key industry” among all industries; Japan’s Mold Association also believes that “molds are the driving force for promoting social prosperity and wealth”, and at the same time, “the secret of the entire industrial development” and “the prime mover for entering a prosperous society”.

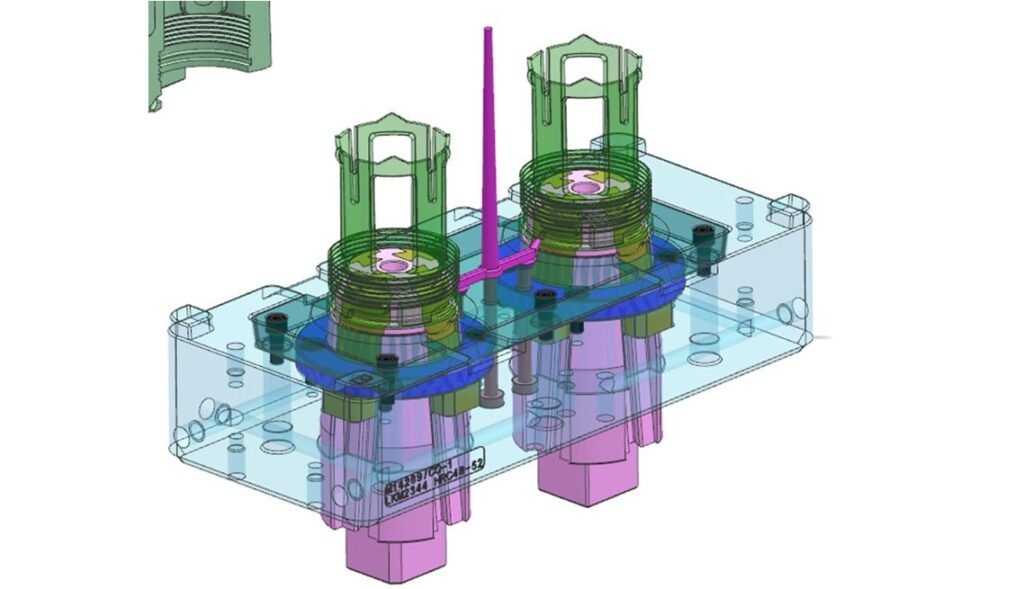

I. Direction of mold opening and parting line

When designing each injection product, the direction of mold opening and the parting line must be determined first to ensure that the core-pulling slider mechanism is minimized and the impact of the parting line on the appearance is eliminated.

After determining the mold opening direction, the reinforcing ribs, buckles, protrusions, and other structures of the product should be designed as much as possible to be consistent with the mold opening direction to avoid core pulling, reduce seam lines, and extend mold life.

After determining the direction of mold opening, select an appropriate parting line to avoid backlash in the direction of mold opening, thereby improving appearance and performance.

II. Demolding slope

- Proper demolding slope can avoid product galling (flowing). The demolding slope of smooth surfaces should be ≥0.5 degrees, fine-grained (sand-like) surfaces should be greater than 1 degree, and rough-grained surfaces should be greater than 1.5 degrees.

- Proper demolding slope can avoid damage to the product, such as top white, top deformation, and top breakage.

When designing deep cavity structural products, the slope of the outer surface should be as large as possible to ensure that the mold core does not shift during injection molding, resulting in uniform product wall thickness and ensuring material strength at the product opening.

III. Product wall thickness

- Various plastics have a certain range of wall thickness, generally ranging from 0.5 to 4mm. When the wall thickness exceeds 4mm, it will cause problems such as excessive cooling time and shrinkage, and consideration should be given to changing the product structure.

- Uneven wall thickness can cause surface shrinkage.

- Uneven wall thickness can cause porosity and weld lines.

IV. Reinforcement

- The rational application of reinforcing ribs can increase the rigidity of products and reduce deformation.

The thickness of the reinforcing rib must be ≤ (0.5-0.7) T of the product wall thickness, otherwise it will cause surface shrinkage.

The single-sided slope of the reinforcing rib should be greater than 1.5° to avoid top damage.

V. Round Corner

- Too small a fillet may cause stress concentration in the product, resulting in cracking.

- Too small a fillet may cause stress concentration in the mold cavity, resulting in cracking of the cavity.

Setting reasonable fillets can also improve the processing technology of the mold, such as directly using R-cutting milling for the cavity, avoiding inefficient electrical processing.

Different fillets may cause the movement of the parting line, and different fillets or clean-up angles should be selected based on the actual situation.

VI. Hole

The shape of the hole should be as simple as possible, generally taking a circular shape.

- The axial direction of the hole is consistent with the mold opening direction, which can avoid core pulling.

When the length-to-diameter ratio of the hole is greater than 2, a demolding slope should be provided. The diameter of the hole should be calculated based on the minimum diameter size (maximum material size).

The aspect ratio of blind holes is generally not more than 4. Anti-hole needle punching and bending

The distance between the hole and the edge of the product is generally greater than the hole diameter.

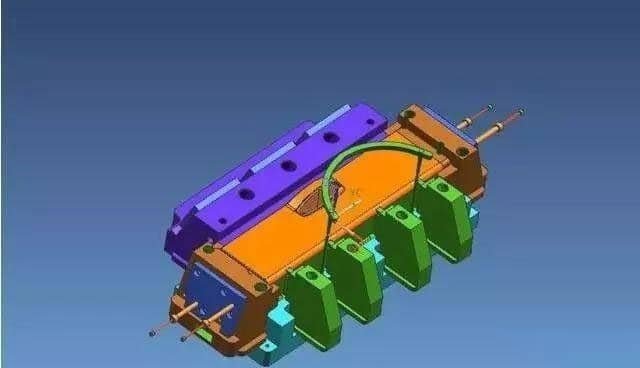

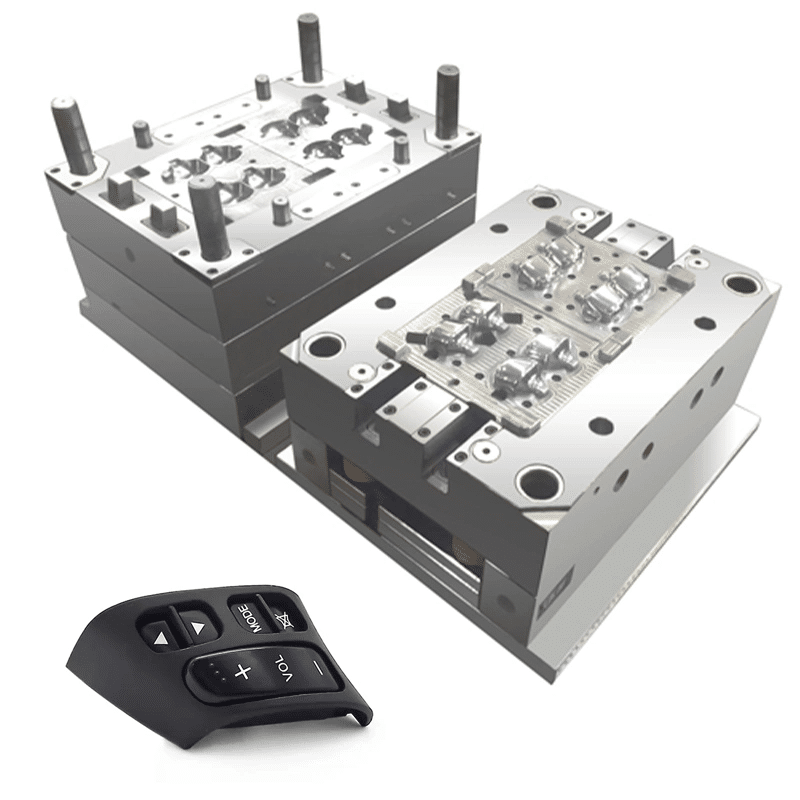

VII. Core pulling, slider mechanism and avoidance of injection molds

When the plastic parts cannot be smoothly released in the direction of mold opening, a core-pulling slider mechanism should be designed. The core-pulling mechanism slider can form complex product structures, but it is prone to defects such as product seam lines and shrinkage, and increases mold costs and shortens mold life.

When designing injection molded products, if there are no special requirements, try to avoid core-pulling structures. For example, change the direction of the hole axis and ribs to the mold opening direction, and use methods such as cavity core penetration.

VIII. Integrated hinge

- Using the toughness of PP material, the hinge can be designed to be integrated with the product.

The size of the film as a hinge should be less than 0.5mm and kept uniform.

When injecting an integrated hinge, the gate can only be designed on one side of the hinge.

IX. Insert

- Incorporating inserts into injection molded products can increase local strength, hardness, dimensional accuracy, and provide small threaded holes (axes) to meet various special needs. At the same time, it will increase product costs.

- The insert is usually made of copper, but can also be made of other metals or plastic parts.

- The part of the insert embedded in the plastic should be designed with rotation-stopping and anti-extrusion structures, such as knurling, holes, bending, flattening, and shaft shoulders.

The plastic around the insert should be appropriately thickened to prevent stress cracking of the plastic part.

When designing the insert, full consideration should be given to its positioning method (holes, pins, magnetic) in the mold.

X. Identification

Product identification is generally set on the relatively flat inner surface of the product, and is in the form of a raised mark. Selecting a surface where the normal direction and mold opening direction may be consistent can avoid pulling damage.

Eleven, precision of injection parts

Due to the unevenness and uncertainty of shrinkage during injection molding, the accuracy of injection molded parts is significantly lower than that of metal parts, and the dimensional tolerances of mechanical parts cannot be simply applied. Proper tolerance requirements should be selected according to standards. In 1993, China also issued GB/T14486-93 “Engineering Plastics Molding Plastic Parts Dimensional Tolerance”, which allows designers to determine the dimensional tolerances of the parts based on the plastic raw materials used and the requirements for the use of the parts, as well as the overall strength of the factory and the design accuracy of the products in the same industry. At the same time, the appropriate design tolerance accuracy should be determined based on the comprehensive strength of the factory and the design accuracy of the products in the same industry.

XII, Deformation of Injection Parts

Improve the rigidity of the injection molding product structure to reduce deformation. Try to avoid flat structure, set up flanging and concave-convex structure reasonably. Set up reasonable reinforcing ribs.

XIII. Button position

- Design the buckle device to be shared by multiple buckles at the same time, so that the overall device will not fail to operate due to damage to individual buckles, thereby increasing its service life. Also, consider adding rounded corners to increase strength.

- The tolerance requirements for the relevant dimensions of the buckle are very strict, and too many buckle positions can easily cause damage to the buckle. Conversely, too few buckle positions can make it difficult to control the assembly position or cause the assembled parts to become loose. The solution is to reserve easy-to-add-glue ways for mold modification.

XIV. Welding (hot plate welding, ultrasonic welding, vibration welding)

- Welding can improve the connection strength.

- Welding can simplify product design.

XIV. Reasonably consider the contradiction between process and product performance

When designing injection molded products, it is necessary to consider the contradictions between product appearance, performance, and process comprehensively. Sometimes sacrificing some processability can achieve good appearance or performance.

- When structural design cannot avoid injection defects, it is best to make the defects occur in hidden areas of the product.

XVI. Relationship between screw stud hole diameter and self-tapping screw diameter

Self-tapping screw screw hole diameter

M2 1.7mm

M2.3 2.0mm

M2.6 2.2mm

M3 2.5mm

XVII.Design principles of BOSS:

1.It is recommended that the pillars not be used alone, but rather be connected to the outer wall or used with reinforcing ribs to strengthen the pillar’s strength and make the rubber flow more smoothly.

2.The height of the pillar is generally not more than two and a half times the diameter of the pillar. Too high a pillar can cause trapped air during the molding of plastic parts (long length can cause air bubbles, scorching, insufficient filling, etc.).

3.If the height of the support exceeds two and a half times the diameter of the support, especially for supports far away from the outer wall, the method to strengthen the strength of the support is to use reinforcing ribs.

4.The shape of the boss is mainly round, and other shapes are not easy to process.

5.The location of the boss cannot be too close to the corner or outer wall, and should maintain a distance from the outer wall of the product.

6.Removing part of the thick meat around the boss (i.e. opening the crater) can prevent shrinkage and subsidence.

7.The angle of the boss for die-pulling: usually take 0.5° outside and 0.5° or 1 inside.