Injection molding is a processing method used in mass production of complex shaped components. The specific principle refers to: the plastic raw materials melted by heat are pushed into the mold cavity of the plastic mold by the screw of the injection molding machine under high pressure, and after cooling and solidification, the plastic formed products are obtained.

I.The plastic mold consists of two parts:

a moving mold and a fixed mold. The moving mold is installed on the moving template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During injection molding, the movable and fixed molds are closed to form the pouring system and cavity. When opening the mold, the movable and fixed molds are separated to remove the plastic product.

The structure of plastic molds may vary greatly due to differences in the variety and performance of plastics, the shape and structure of plastic products, and the type of injection machine, but the basic structure is consistent.

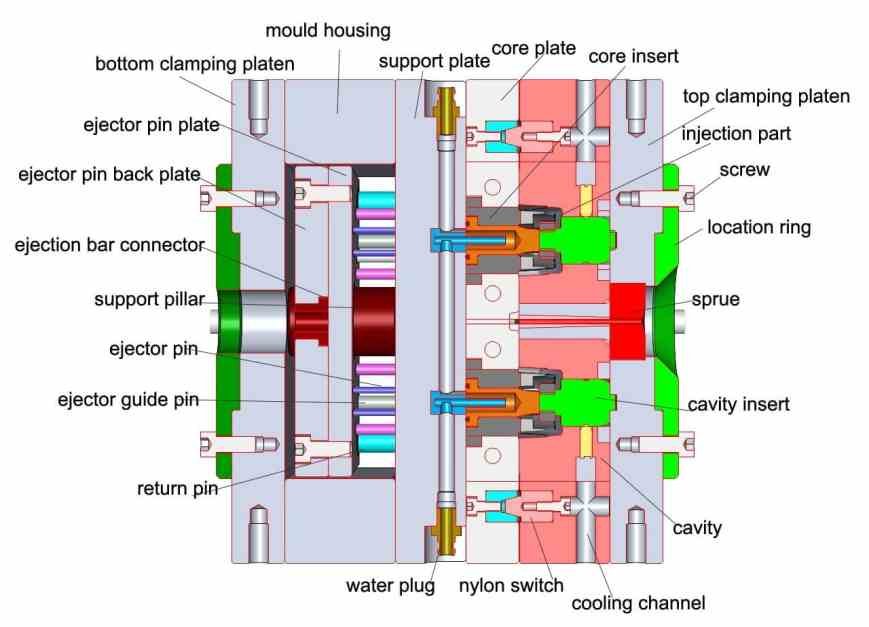

1.The structure of plastic molds is mainly composed of pouring system, temperature control system, formed parts system, exhaust system, guiding system, ejection system, etc. according to their functions. The pouring system and formed parts are the parts that come into direct contact with plastic and vary with the plastic and the product. They are the most complex and variable parts in plastic molds, requiring the highest processing smoothness and accuracy.

- Pouring system: refers to the flow channel part of plastic before entering the mold cavity from the nozzle, including the main flow channel, cold material hole, diversion channel, and gate.

- Formed parts system: refers to various combinations of parts that form the shape of a product, including moving molds, fixed molds, and cavities (concave molds), cores (convex molds), forming rods, etc. The core forms the inner surface of the product, and the cavity (concave mold) forms the outer surface shape of the product. After the mold is closed, the core and cavity form the cavity of the mold. According to the requirements of technology and manufacturing, sometimes the core and die are composed of several assembled blocks, and sometimes they are made into a whole. Only inserts are used in areas that are prone to damage and difficult to machine.

- Temperature control system: In order to meet the temperature requirements of the injection process for the mold, a temperature control system is required to adjust the temperature of the mold. For injection molds for thermoplastic materials, the main approach is to design a cooling system to cool the mold (which can also be heated). The common method of mold cooling is to set up a cooling water channel inside the mold, and use the circulating cooling water to take away the heat of the mold; The heating of the mold can not only utilize cooling water to pass through hot water or oil, but also install electric heating elements inside and around the mold. 4. Exhaust system: It is set up to exhaust the air and gas generated by the melting of plastic inside the injection molding process to the outside of the mold. When the exhaust is not smooth, the surface of the product will form air marks (air marks), burning and other defects; The exhaust system of plastic molds is usually a groove shaped air outlet set up in the mold to exhaust the air in the original cavity and the gas brought in by the molten material.

- Exhaust system: When the molten material is injected into the mold cavity, the air originally stored in the cavity and the gas brought in by the molten material must be discharged outside the mold through the exhaust port at the end of the material flow. Otherwise, it will cause the product to have pores, poor connections, insufficient mold filling, and even accumulate air that generates high temperatures due to compression, causing burns to the product. In general, the exhaust hole can be located at the end of the molten material flow in the mold cavity or on the parting surface of the plastic mold. The latter involves opening a shallow groove on one side of the concave mold, with a depth of 0.03-0.2mm and a width of 1.5-6mm. During injection, there will not be a lot of molten material seeping out of the exhaust hole, as the molten material will cool and solidify at that location, blocking the channel. The opening position of the exhaust port should not face the operator to prevent accidental spraying of molten material and injury. In addition, the clearance between the ejection rod and the ejection hole, as well as the clearance between the ejection block, the template, and the core can also be used for exhaust.

- Guiding system: It is set up to ensure accurate alignment between the moving and fixed molds during mold closing, and guiding components must be installed in the mold. In injection molding, four sets of guide pillars and guide sleeves are usually used to form guiding components. Sometimes, matching inner and outer conical surfaces need to be set on the moving and fixed molds to assist in positioning. 6. Ejection system: generally consists of several parts, including: ejector pin, front and rear ejector pin plates, ejector pin guide rods, ejector pin reset springs, ejector pin plate locking screws, etc. After the product is formed and cooled in the mold, the front and rear molds of the mold separate and open. The ejection mechanism – the ejector pin – pushes the plastic product and its condensate in the flow channel out or out of the mold opening and flow channel position under the push of the top rod of the injection molding machine, so as to proceed with the next injection molding work cycle.

II.Plastic mold Structure and Composition

Plastic molds are generally composed of several parts according to their structure, including mold frame, mold core, auxiliary parts, auxiliary system, auxiliary settings, dead angle treatment mechanism, etc.

- Mold frame: Generally, we do not need to design it. You can order it directly from a standard mold frame manufacturer, which greatly saves the time required for mold design. Therefore, it is called a plastic mold standard mold frame. It forms the most basic framework part of plastic molds.

- Mold core: The mold core is the core part of a plastic mold, and it is the most important component inside the mold. The forming part of plastic products is inside the mold core, and most of the processing time is also spent on the mold core. However, compared to some relatively simple molds, they do not have a core part and the product is directly formed on the template. Early plastic molds were mostly like this, relatively backward.

- Auxiliary parts: Commonly used auxiliary parts for plastic molds include positioning rings, injection sleeve, ejector pin, grabbing pin, support column, ejector plate guide column guide sleeve, garbage nails, etc. Some of them are standard parts that can be ordered together with the mold frame, while others require self design.

- Auxiliary System: There are four auxiliary systems for plastic molds: pouring system, ejection system, cooling system, and exhaust system. Sometimes, due to the high temperature required for heating the plastic materials used, some molds may also have a heating system. 5. Auxiliary settings: The auxiliary settings for plastic molds include lifting ring holes, KO holes (top rod holes), and so on. 6. Dead corner processing structure: When plastic products have dead corners, the mold will also have one or more structures for processing dead corners. Such as sliders, inclined roofs, hydraulic cylinders, and so on. In most domestic books, this type of mechanism for handling dead corners is referred to as a “stamen pulling mechanism”.

In fact, plastic molds are not difficult. No matter how the plastic product changes, the structure of the mold used to shape this plastic product is nothing more than the above aspects. The difference between molds lies in whether they are large or small? The positions or methods of each auxiliary component, auxiliary setting, and auxiliary system are different. The method, structure, and size of handling dead corners have only changed. Of course, in order to make the designed mold easy to process, easy to assemble, have a long lifespan, be reasonably priced, and have good formed products, design experience is particularly important. Good experience can handle problems that arise during design and processing, and is also confident in handling design changes.

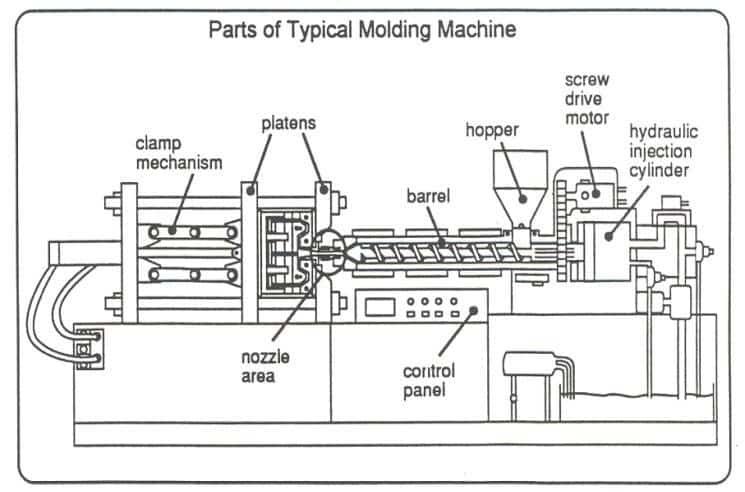

III.The structural composition of an injection machine:

A universal injection machine mainly includes an injection device, a mold closing device, a hydraulic transmission system, and an electrical control system. The main function of the injection device is to uniformly plasticize the plastic and inject a certain amount of molten material into the mold cavity with sufficient pressure and speed. The injection device mainly consists of plasticizing components (composed of screws, barrels, and nozzles), as well as hoppers, transmission devices, measuring devices, injection and moving oil cylinders, etc.

Mold closing device: Its function is to achieve the opening and closing of the mold, ensure the reliable tightening of the molding mold during injection, and release the product. The mold closing device mainly consists of front and rear fixed templates, mobile templates, pull rods used to connect the front and rear templates, mold closing oil cylinders, connecting rod mechanisms, mold adjustment devices, and product ejection devices. Hydraulic system and electrical control system: Their function is to ensure that the injection machine operates accurately and effectively according to the predetermined requirements of the process (pressure, speed, temperature, time) and action sequence. The hydraulic system of the injection machine is mainly composed of various hydraulic components, circuits, and other auxiliary equipment, while the electrical control system is mainly composed of various electrical appliances and instruments. The hydraulic and electrical systems are organically organized together to provide power and control for the injection machine.