Brass Insert Molding for Auto Parts

Our brass insert molding can be found in many parts of an automobile’s interior and exterior design as well as electrical connectors – making this material highly flexible in application.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

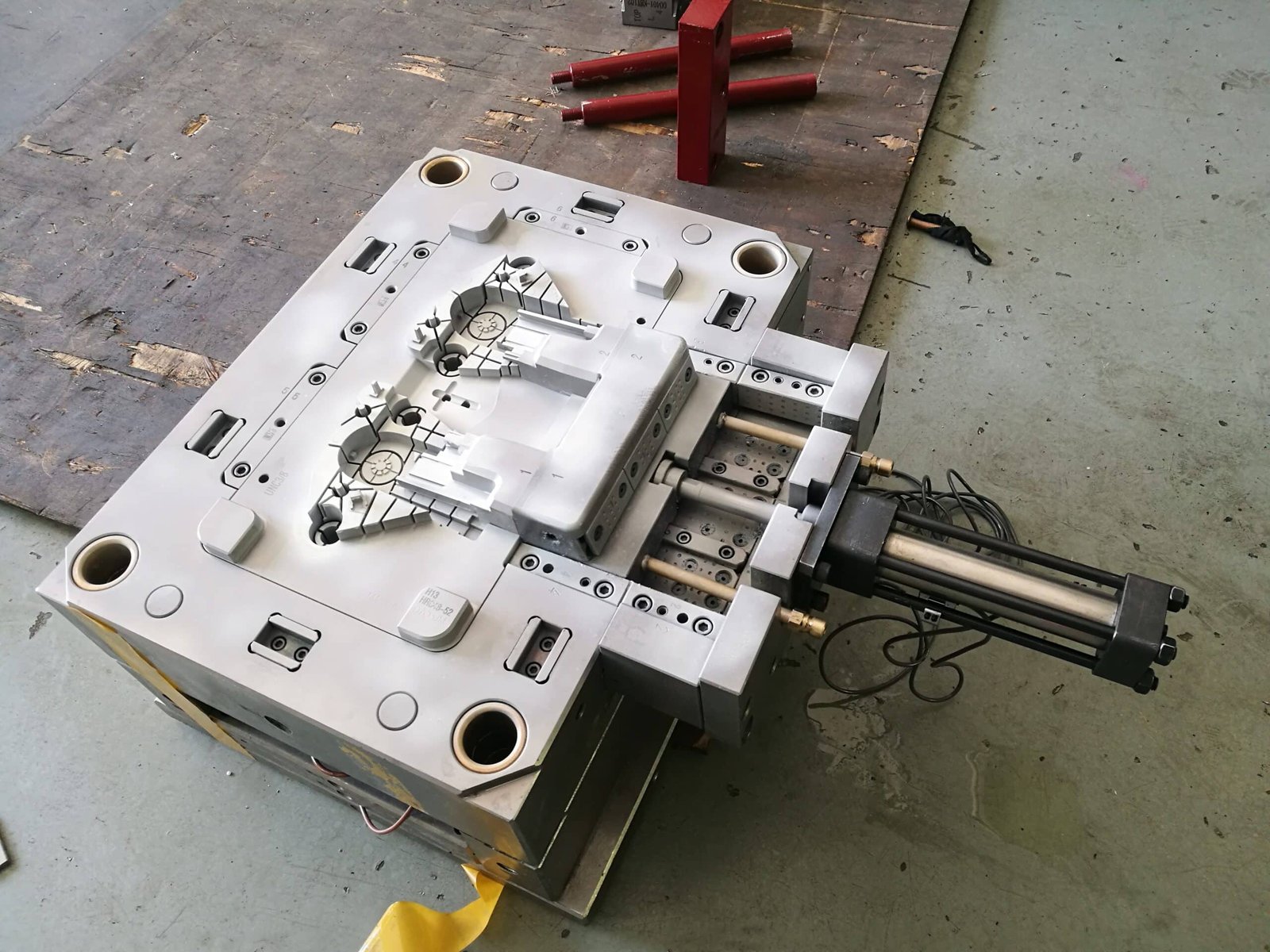

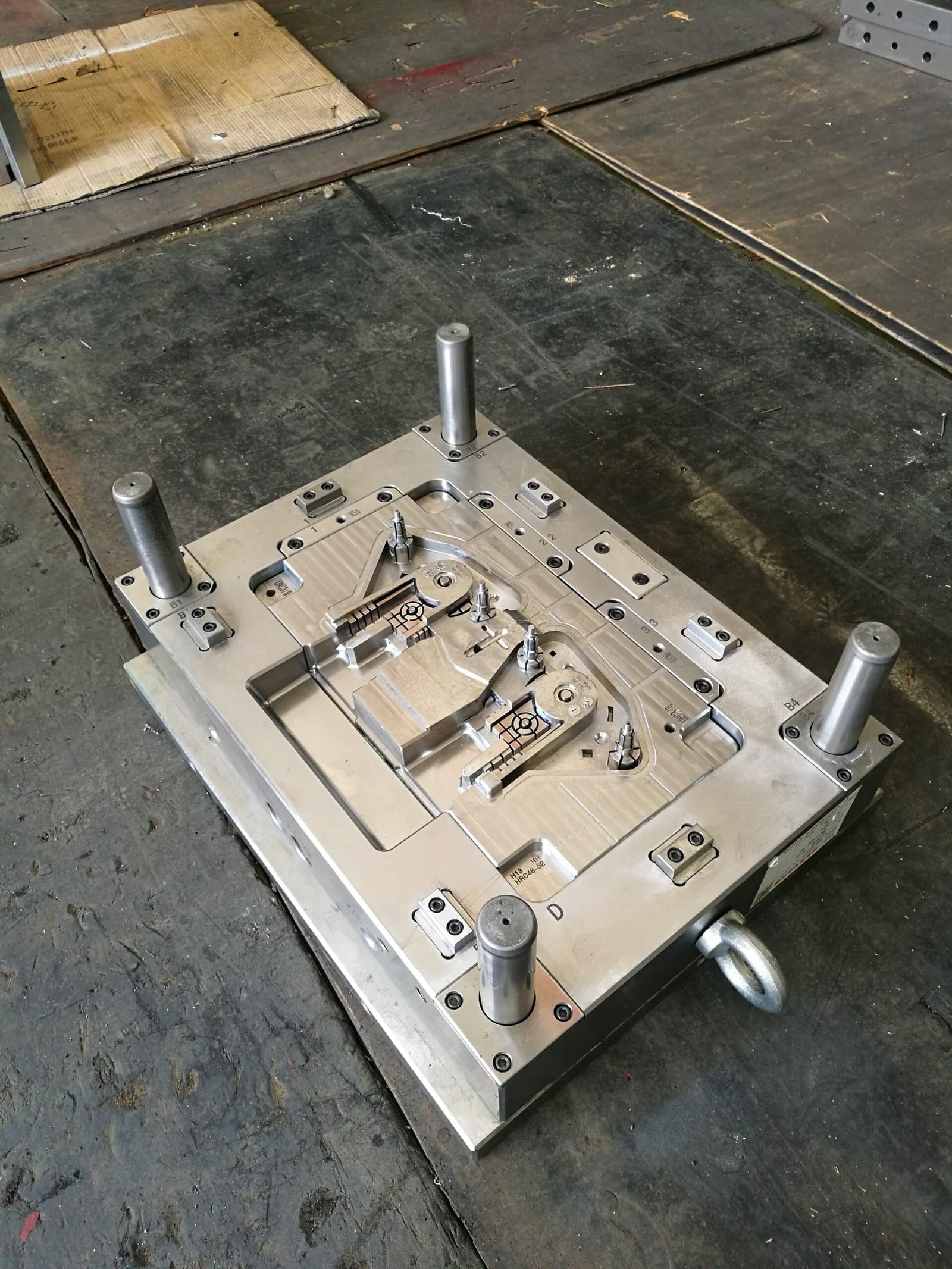

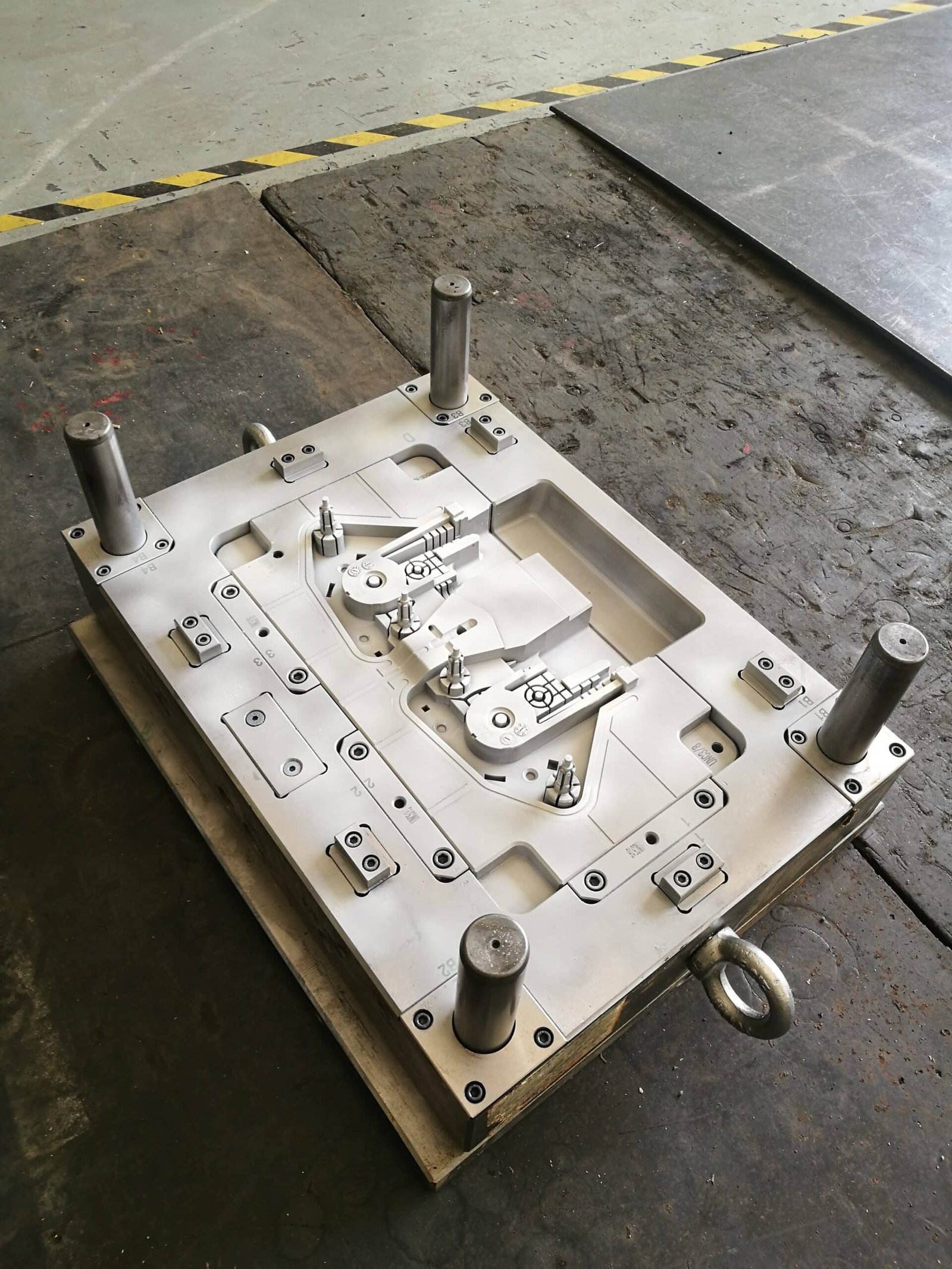

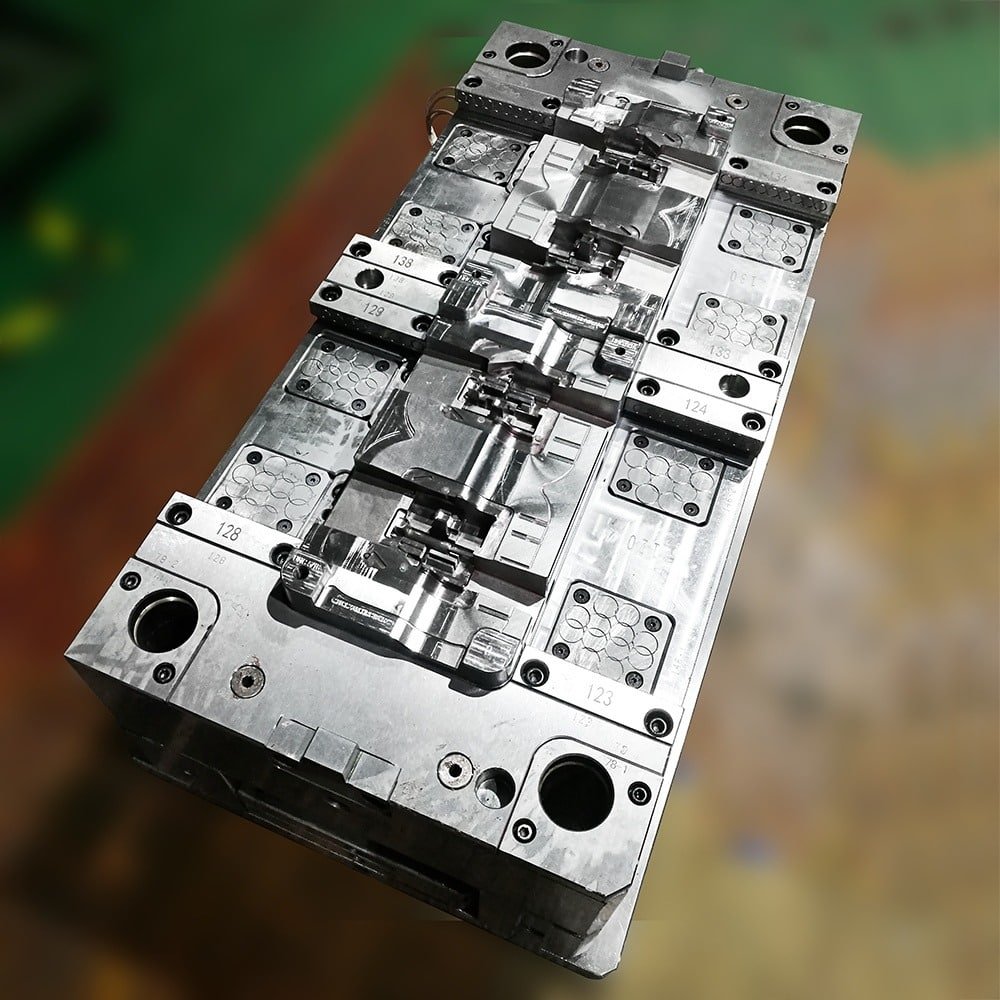

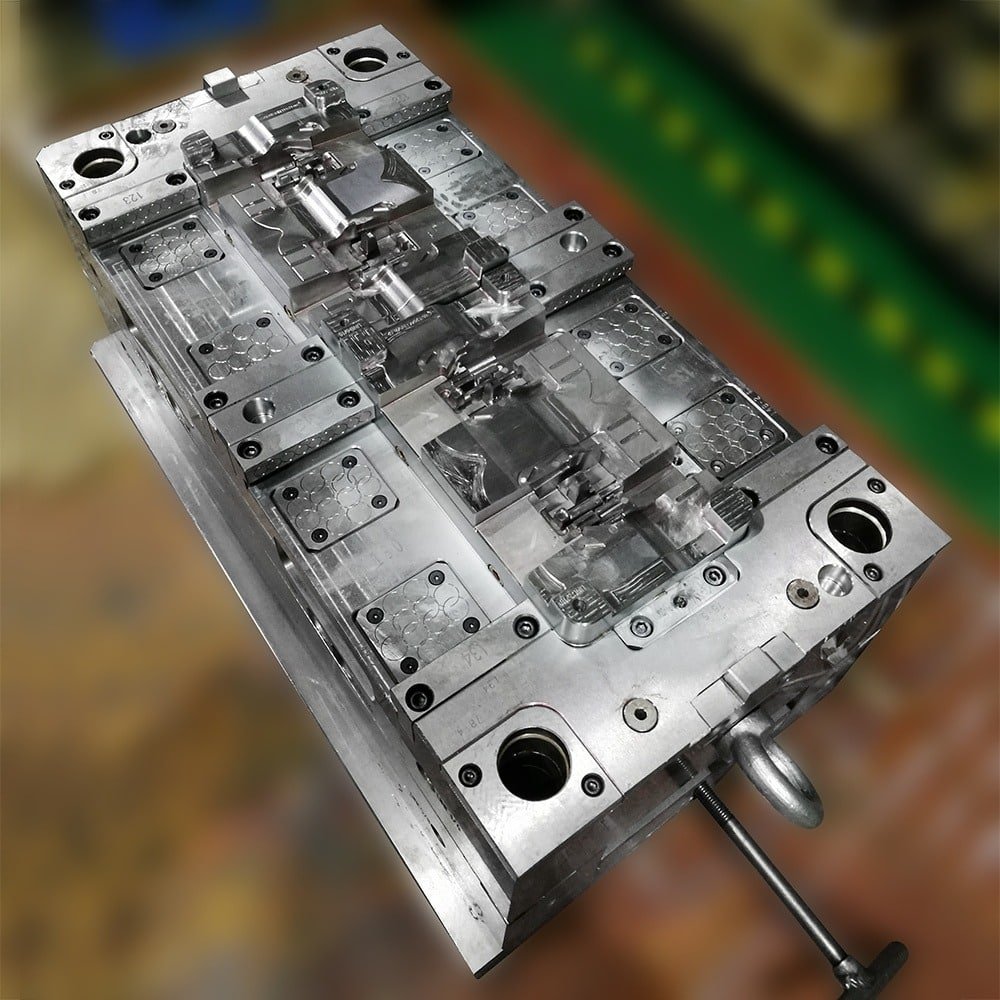

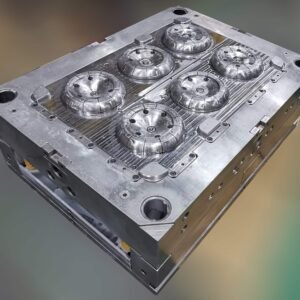

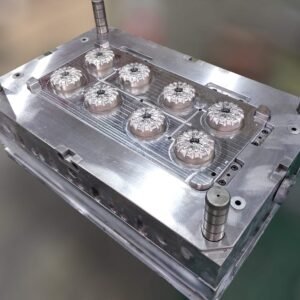

Mold features:

- Hydraulic cylinder core pull/ slides.

- Insert molding/ metal insert mould.

- Plastic components for auto parts.

| Tool No. | M17069 |

| Part Name | 16937461 |

| Plastic material | PP+30%GF |

| Shrinkage rate | 1.003 |

| Color | Black |

| Part Finish | SPI-B3 |

| Cavity No. | 1LH+1RH |

| Cavity and Core Steel | H13 (HRC 48-52) |

| Slide Steel: | H13 (HRC 48-52) |

| Mold Base | 1050 |

| Standard components | DME English standard |

| Gate Type | Cold runner SUB gate |

| Manufacturing Date | May 17, 2017 |

Product Features

Our brass insert molding for auto parts offers several key benefits:

1.Enhanced Durability: Brass inserts offer increased strength and longevity to automotive components, prolonging their service lives for years to come.

2.Corrosion Resistance:Brass’ high corrosion-resistance makes it ideal for automotive applications exposed to various environmental conditions, making this material suitable for auto applications in any environment.

3.Precision:Insert molding allows for precise placement of brass inserts within plastic components for accurate assembly and performance, providing accurate assembly instructions as well as reliable performance results.

4.Vibration Damping:Using brass inserts can significantly decrease vibration and noise pollution, and improve driving experiences overall.

5.Cost-Effective: Insert molding can streamline manufacturing, cutting down production costs compared to more traditional assembly techniques.

6.Application:Brass insert molding can be found in many parts of an automobile’s interior and exterior design as well as electrical connectors – making this material highly flexible in application.