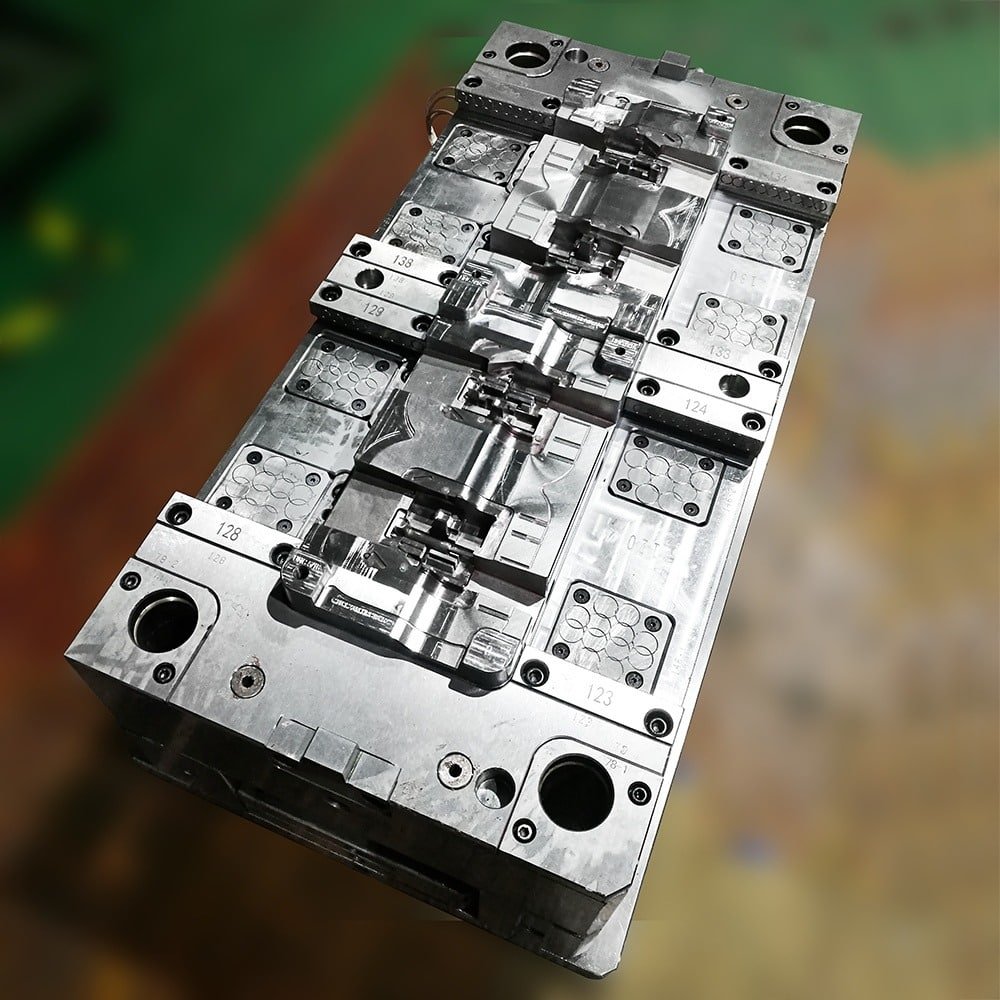

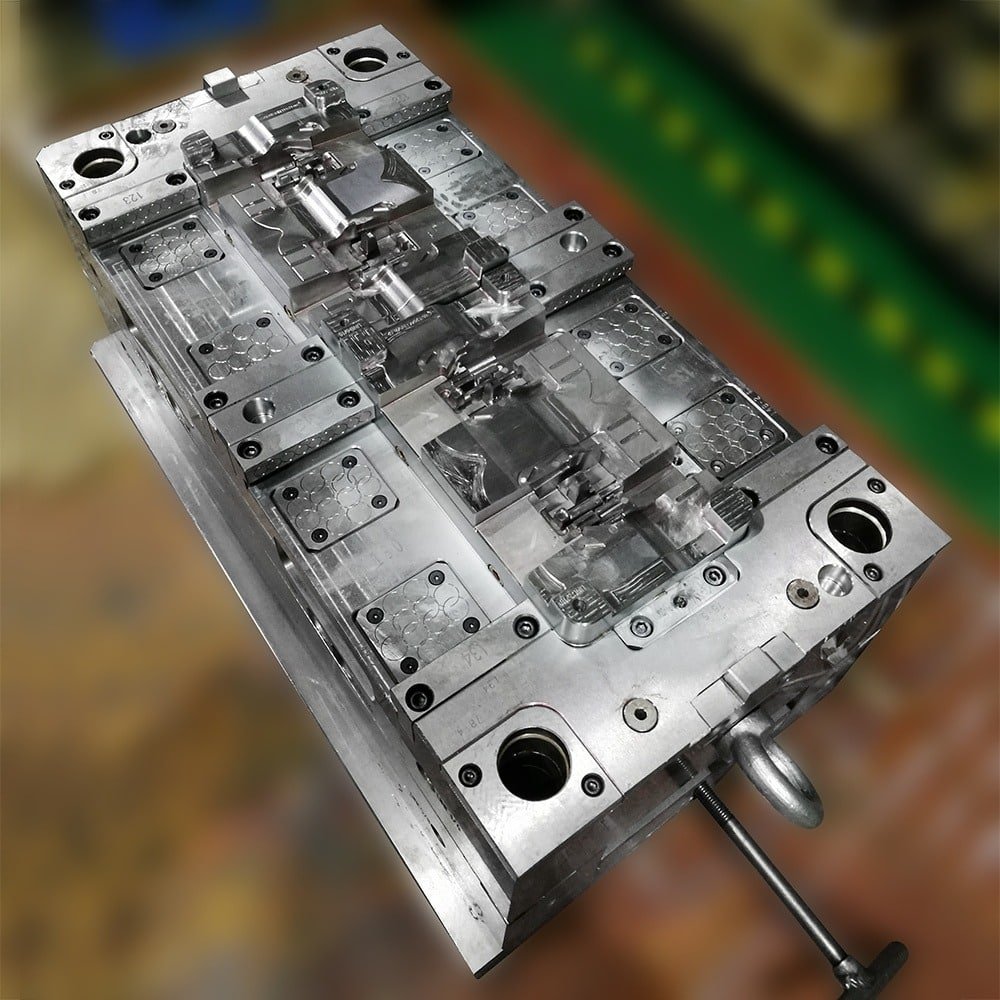

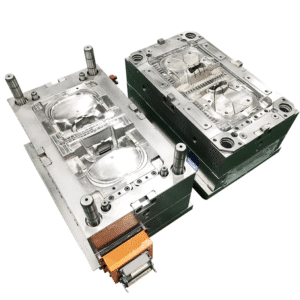

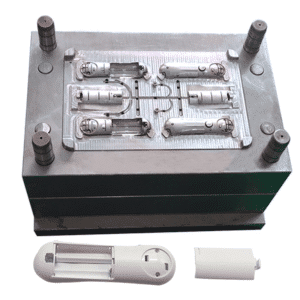

Plastic Insert Mould Injection Molding Parts For Industrial Equipment

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

Part function: Plastic component for industrial equipment

Part material: PA66+30%GF

Shrink rate: 5/1000

Part finish: MT-11030

Color: Black

Cavity: 1 cavity/ single cavity

Gate type: Incoe hot runner system

Cavity and core steel: H13 (48-52HRC)

Mold base: 1050

Standard components: Hasco standard

Injection molding machine size: 320T

Product Features

Plastic insert mold injection molding parts for industrial equipment boast several key product attributes, such as:

1. Increased Strength and Durability: Insert molding is an innovative technique which incorporates metal reinforcements or reinforcing materials directly into plastic components for increased strength and durability that will stand up against demanding industrial applications.

2. Cost-Effective Manufacturing: By combining various materials together in one mold process, insert molding can drastically decrease assembly costs while producing complex yet integrated components to save costs during manufacturing processes. This creates significant cost efficiencies throughout their total manufacturing life cycle.

3. Increased Component Integration: Insert molding allows the incorporation or incorporation of inserts such as threaded metal inserts, connectors or electronic components directly into plastic parts to improve component integration, simplifying assembly while increasing reliability of parts.

4. Design Flexibility: 3D printing allows designers to produce intricate part designs utilizing complex geometries that would otherwise be difficult to reproduce through traditional assembly methods, providing greater design freedom when creating industrial equipment components.

5. Environmental Resistance: By selecting resistant materials in insert molding, inserts can protect industrial equipment parts against chemicals, temperature variations and other environmental elements – thus increasing longevity and reliability for years.

These features contribute to the creation of durable, cost-effective plastic injection molded parts suitable for industrial equipment that meet stringent performance demands.