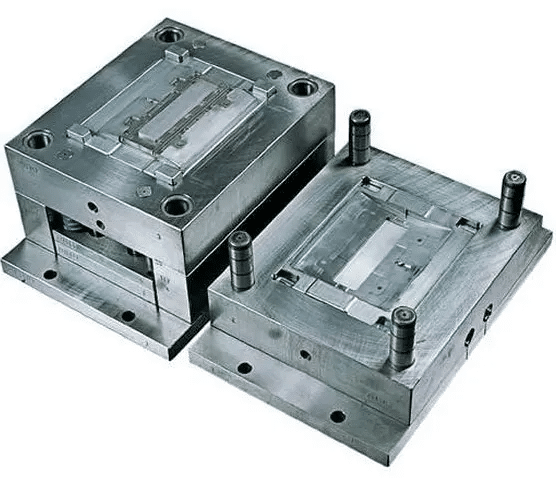

Custom Hot Runner Complex Injection Mold For Plastic Housing Parts

Overall, our custom hot runner injection molds for plastic housing parts offer precision, customization, durability and efficiency – ideal features in applications spanning industries including automotive, electronics and consumer goods.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Place of Origin | Guangdong, China |

| Brand Name | YCH Mold |

| Model Number | YCHHM-20030283 |

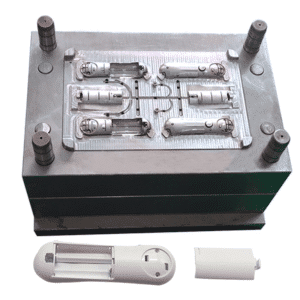

| Product Material | Plastic |

| Product | Household Appliance |

| Product Name | Molding/moulding |

| Standared | LKM DME HASW |

| Core and Core Material | S136, NAK80, 1.2344, 738, 738H, P20, 718, SKD61, 718H |

| Texture | VDI, YS, Mt |

| Mold Base | LKM, HASCO, DME |

| product material | ABS PP PA66+GF PC |

| mold life | 500K to 1000K |

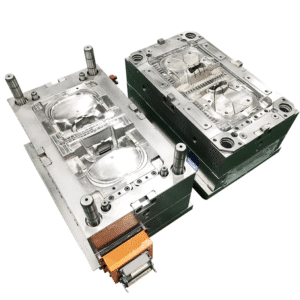

| mould cavity | two cavity |

| packaging | carton |

| emote control size | 210*38*12mm |

| Packaging Details | Carton Board for finished plastic parts or special packing as per customer’s requirement, |

| Port | Shenzhen |

Product Features

Our custom hot runner complex injection molds for plastic housing parts provide many key features:

1.Precision Molding: These precision molds are engineered for high accuracy to deliver accurate and consistent molding of complex plastic parts with tight tolerances, while maintaining accurate precision molding of complex parts.

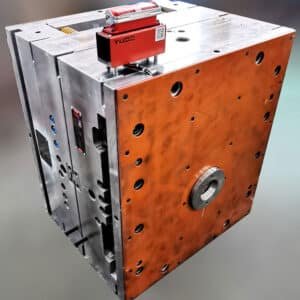

2.Hot Runner System: Integrating a hot runner system allows for efficient, controlled injection of liquid plastic into mold cavities reducing cycle times and waste material usage.

3.Customization: Each mold can be tailored to meet specific design specifications, from intricate geometries and undercuts to unique part features allowing the production of highly tailored plastic housing parts.

4.Durability: These molds, built using high-grade materials such as hardened steel or aluminum alloys, are constructed for long-term durability and reliability in high volume production environments.

5.Optimized Cooling: Cutting-edge cooling channels have been integrated into mold designs in order to allow rapid and uniform cooling of plastic injection. This reduces cycle times while improving part quality.

6.Efficient Production: Utilizing sophisticated design and manufacturing technologies, these molds maximize production efficiency for faster turnaround times and reduced overall manufacturing costs.

7.Quality Control Measures: Stringent quality assurance procedures are implemented throughout our manufacturing processes to ensure each mold meets stringent quality and performance criteria, ultimately producing consistently superior plastic parts.

Overall, our custom hot runner injection molds for plastic housing parts offer precision, customization, durability and efficiency – ideal features in applications spanning industries including automotive, electronics and consumer goods.