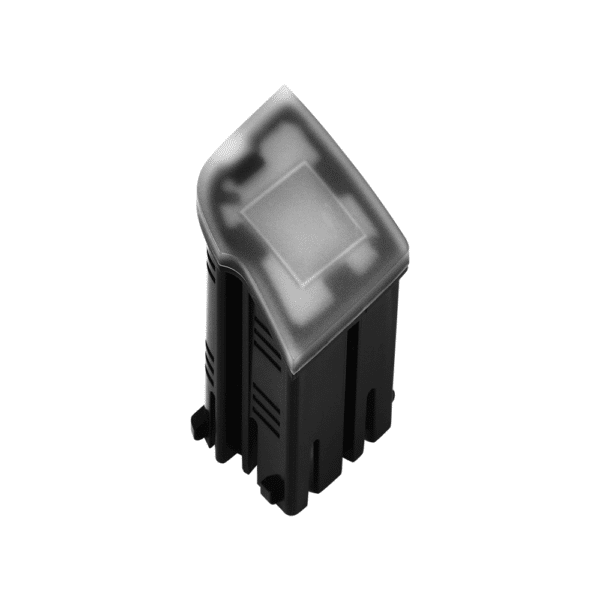

Custom Precision Electrical Household Plastic Injection Molding Parts

Quality Control Measures: Adherence to rigorous quality assurance practices throughout the manufacturing process is imperative in guaranteeing both reliability and safety for electrical parts.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Model NO. | YCHMP-189 |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| Product Shaping Mode | Plastic Injection Mould YCH-189 |

| Mould Base | Lkm, Dme, Hasco etc ; |

| Steel Hardness | 20-60HRC |

| Treatment | Pre-Harden, Nitride, Heat Treatment, Quenching |

| Mould Life | 50K – 1 Million Cycles |

| Product Design Software | Ug, CAD, PRO-E, Solid Works etc |

| Quality | ISO9001:2000 Certified |

| Payment | T/T, Western Union , Money Gram |

| Transport Package | Crate/Pallet |

| Specification | 1000T double injection |

| Trademark | Win Win Mold |

| Origin | Shenzhen,China |

| HS Code | 8480719099 |

| Production Capacity | 500 Molds/ Year |

Product Features

1. Tight Tolerances: Precision molding ensures parts manufactured meet specific design specifications with very tight tolerances.

2. Material Selection: Selecting high-grade plastic materials that can withstand electrical environments is of vital importance in terms of performance and lifespan of parts used in electronic applications.

3. Complex Geometry: Injection molding allows for intricate part designs with complex geometries to meet specific home application specifications, providing customers with customized items suited for electrical usage in their household appliances.

4. Surface Finish: Consistent and high-quality surface finishing is vitally important to both aesthetics and functionality in electrical parts, especially.

5. Dimensional Stability: For reliable electrical applications, parts must maintain their shape and dimensions despite different environmental conditions to guarantee reliable performance.

6.Customization: One key feature is being able to tailor parts according to specific electrical specifications – be they connectors, housings or any other component.

7. Quality Control Measures: Adherence to rigorous quality assurance practices throughout the manufacturing process is imperative in guaranteeing both reliability and safety for electrical parts.