Multi-Material Plastic Injection Overmolding Parts For Automotive Parts

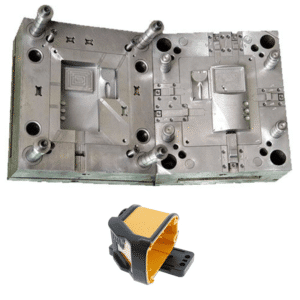

Mold features:

- Industrial structural part.

- Bi-injection mold/double injection mold/ 2 shot mold/2k injection moulding technology/ two-color mould.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Shaping Mode | Plastic Injection Mould |

| Place of Origin | Shenzhen, China |

| Brand Name | YCH Mold |

| Product Material | Plastic |

| Product Name | plastic molding parts |

| Application | Matte, Glossy, high polish, Mirror polishing, Texture, Chrome plating |

| Material | ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT |

| Mould material | P20/718/738/NAK80/S136/2738/2316 |

| Design software | 2D/3D/CAD/DWG//STEP/PDF/UG |

| Color | Customized Colors |

| Size | Customized Size |

| Mould Life | 250000-300000shots |

| Surface treatment | Matte, Glossy, Texture, Silk screen, Chrome plating, Spray painting |

Product Features

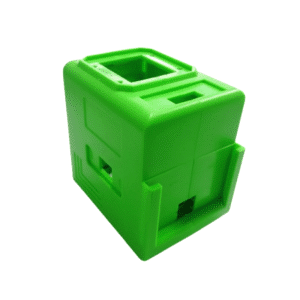

Part function: Component for automotive industry

Part material: ABS+TPE

Mold features:

1.Bi-injection mold/double injection mold/ 2 shot mold/2k injection moulding technology/ two-color mould.

2.Complex Geometries:Overmolding can create intricate geometries which traditional molding methods would struggle to reach; this makes overmolding ideal for automotive parts with intricate designs that may present difficulty for traditional methods to reach.

3.Enhanced Functionality:By layering materials together in various configurations, it is possible to produce parts with varied properties; such as soft-touch grips and vibration dampening features or durable outer shells featuring inner softer layers for impact absorption.

4.Reduced Weight: By strategically using lightweight materials during overmolding processes, manufacturers can significantly decrease overall component weight for improved fuel economy and performance.