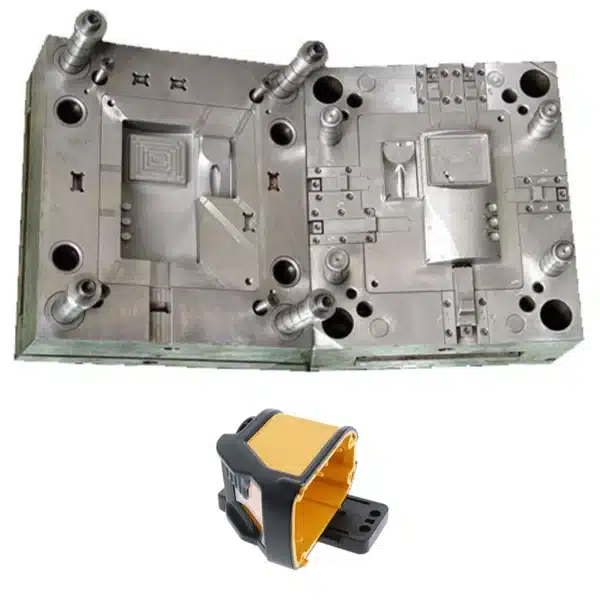

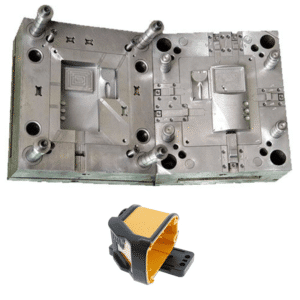

Plastic Injection Overmold for Architectural Measuring Instrument Shell

Precision Overmolding:Ensure precise overmolding to seamlessly integrate different materials, like rubber or TPE, for enhanced grip and shock absorption.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Model NO. | YCH-OV-20231269 |

| Plastic Material | PC |

| Process Combination Type | Single-Process Mode |

| Application | Household Appliances, Electronic, Home Use |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | Lkm |

| Customized | Customized |

| Mould Material | S316h, Nak80, 718h |

| Hardness | 45-56 HRC |

| Parts Material | ABS, PC, PA66, PP, TPU, etc. |

| Mould Life | 500K~1000K Shots |

| Item | Plastic Injection Overmold for Architectural Measuring Instrument Shell |

| Transport Package | Wooden Box |

| Specification | customization |

| Trademark | OEM |

| Origin | Shenzhen, China |

| HS Code | 8480719069 |

| Production Capacity | 60 Sets / Month |

Product Features

Here are a few features of our plastic injection overmold for architectural measuring instrument shell:

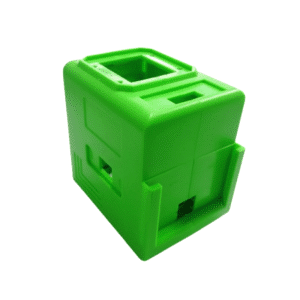

1.Material:Utilizing impact-resistant materials such as ABS or PC-ABS to create your shell can extend its longevity over time.

2.Ergonomic Design:The ergonomic features and grips designed into this product allow for comfortable usage over long hours of operation.

3.Color Options: Provide different color choices to meet the branding or preferences of end users.

4.Precision Overmolding:Ensure precise overmolding to seamlessly integrate different materials, like rubber or TPE, for enhanced grip and shock absorption.

5.Seamless Integration of Components:Design the overmold to ensure seamless incorporation of any electronic components or interfaces needed for measuring instrument.

6.Weather Resistance: Ensuring an overmold offers protection from environmental elements like moisture and dust is critical in maintaining accuracy and functionality of an instrument.

7.Custom Branding:Enable custom logos or branding elements on an overmolded shell for personalization.

8.Compatibility:Ensure the overmolded shell remains compatible with existing accessories or attachments used with your measuring instrument.