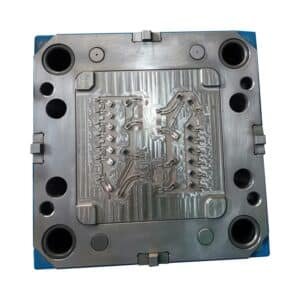

TPE Multi Cavity Injection Auto Plastic Parts

Due to the complex variability of two-color mold injection molding, in order to meet production and satisfy expected ideals smoothly, all mold design must be integrated simultaneously with product design; specifications of popular two-color injection molding machines do not correspond consistently resulting in additional issues for mold designers to consider when creating mold designs;

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

Description

| Model NO. | YCH2M-007 |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| Product Shaping Mode | Plastic Injection Mould Ww-005 |

| Mould Base | Lkm, Dme, Hasco etc ; |

| Steel Hardness | 20-60HRC |

| Treatment | Pre-Harden, Nitride, Heat Treatment, Quenching |

| Mould Life | 50K – 1 Million Cycles |

| Product Design Software | Ug, CAD, PRO-E, Solid Works etc |

| Quality | ISO9001:2000 Certified |

| Payment | T/T, Western Union , Money Gram |

| Transport Package | Crate/Pallet |

| Specification | 1000T double injection |

Product Features

Mold features:

- Industrial structural part with unscrewing thread.

- Bi-injection mold/double injection mold/ 2 shot mold/2k injection moulding technology/ two-color mould.

- Hydraulic cylinder core pull to form the thread

Part function: Component for Industrial Equipment

Part material: PC+TPE

What are the advantages of two-color injection molding

1. Double color mold injection molding can serve as an economical and one-step alternative for products featuring different inner and outer plastic layers, replacing secondary processing steps with direct molding of both plastics layers in one molding operation.

2. Thanks to different color combinations, two-color injection molds can give old products (molds) new life by reinvigorating their design with different hues. Core materials using low viscosity raw materials help reduce injection pressure significantly.

3. Two color mold injection molding is not only the combination of two or multiple colors of plastics, but it also places greater demands upon injection molding machines in terms of product accuracy, beautiful appearance, integration between colors plastics, molding cycle speed etc.

4. A two-color injection molding machine designed for two-color injection molding can also be used to produce monochrome products; providing one machine for dual functions and providing all-round services; the core material can use recycled waste or lower quality raw materials in order to minimize costs; higher quality materials that feature special surface properties or anti electromagnetic interference can help boost product performance; while proper mixing between core material and skin material helps minimize residual stress and maximize strength in products produced using this process.

Due to the complex variability of two-color mold injection molding, in order to meet production and satisfy expected ideals smoothly, all mold design must be integrated simultaneously with product design; specifications of popular two-color injection molding machines do not correspond consistently resulting in additional issues for mold designers to consider when creating mold designs; additionally mold manufacturers must pay extra attention when dealing with limited versatility of their machines.