Overmold (secondary molding): Two plastic materials are not necessarily injected on the same injection molding machine, and are formed twice; after the product is removed from one set of molds, it is placed in another set of molds for a second injection molding process.

When designing the overmold, attention should be paid to the positioning of the hard rubber parts, and reliable sealing is required. Moreover, there should be anti-slope holes on the rubber parts to prevent deformation caused by pulling the rubber. The rubber injection mould requires full consideration of the dimensions of the rubber parts, the rubber injection process, the accuracy of the mould, the positioning of the product, and the operation and retrieval. The dimensional accuracy is doubled compared to that required for ordinary injection moulds.

Although the accuracy requirements for two-shot injection molds are also very strict, overmold injection molds are more complex than two-color injection molds. Two-color injection molding is completed on the same injection molding machine, and the dimensional fluctuations of the product are not yet fully evident during the first molding process, as the product has not yet fully cooled.

The application of plastic injection molding processing technology: appearance products, conductive products, power-off terminals, hardware handles, product reinforcement, waterproof products, electrical products, beauty supplies, maternal and child supplies, household small appliances, electric fans, new energy vehicles, game consoles, sports equipment, nightlights, table lamps and other application fields are very wide.

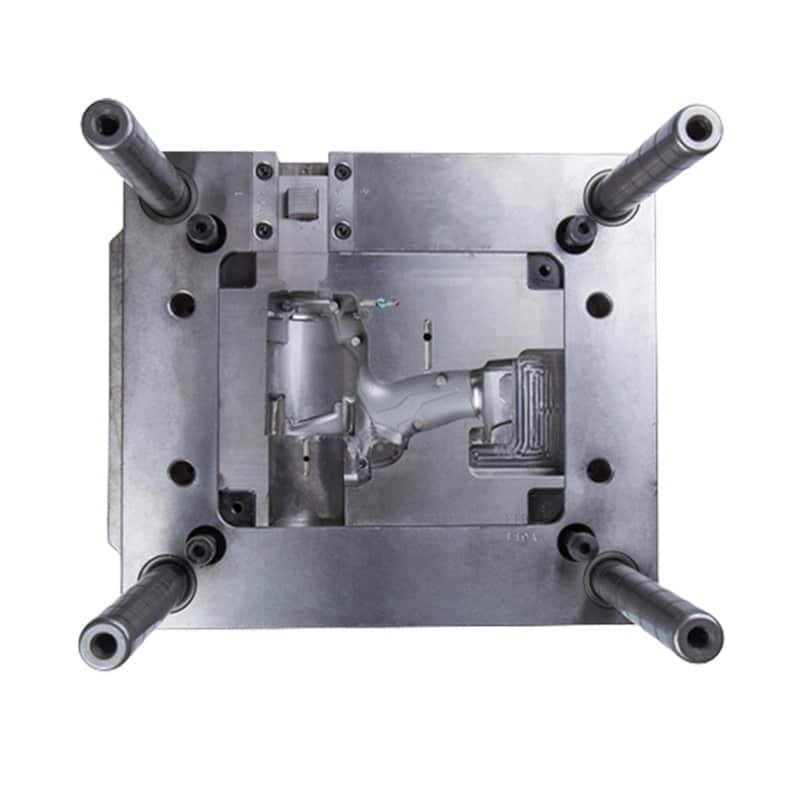

Two-Shot Mold: Two plastic materials are injected and molded twice on one injection molding machine, but only the product is created once. This process, known as two-shot molding, usually utilizes multiple molds with separate colors that use special two-shot mold machines to form two-color molds for two-shot molding processes that produce two-shot molds with ease – but can be expensive and require high technical requirements for completion. Two-Color Molds have become increasingly popular as an option because it makes products appear more elegant while making color changes simple without spraying; however this requires specialization with two sets of molds dedicated two-shot machines to get perfect two-shot molding.

The front and rear molds of the two-color mold must be aligned after rotating 180 degrees from the center. This check must be performed during design. It is recommended that the sprues of the three-plate mold be designed to have automatic demolding action. Special attention should be paid to the reliability of the demolding action of the soft plastic sprues.

Application of two-shot injection molding technology: Two-color injection molding has been widely applied to almost all plastic fields such as electronic products, power tools, medical products, home appliances, toys, etc. The production and molding of two-color molds, as well as the research and development of two-color and multi-color injection molding machines and two-color injection molding raw materials have also developed rapidly.