A mold is composed of many parts, the quality of the parts directly affects the quality of the mold, and the final quality of the parts is guaranteed by finishing, so it is important to control the finishing. In most domestic mold manufacturing enterprises, the methods used in the finishing stage are generally grinding, electric machining and fitter treatment. At this stage to control parts deformation, internal stress, shape tolerance and dimensional accuracy and many other technical parameters, in the specific production practice, the operation is more difficult, but there are still many effective experience methods worth learning.

Mold parts processing, according to the appearance of different shapes of parts, parts can be roughly divided into three categories: plate, shaped parts and shaft, the common process is roughly: roughing – heat treatment (quenching, tempering) – fine grinding – electrical machining – fitter (surface treatment) – assembly processing.

1 Parts heat treatment

The heat treatment process of the parts, while making the parts obtain the required hardness, it is also necessary to control the internal stress to ensure the stability of the dimensions during the processing of the parts, and different materials have different treatment methods. With the development of mold industry in recent years, the types of materials used have increased, in addition to Cr12, 40Cr, Cr12MoV, cemented carbide, for some of the large work strength, the force harsh convex, concave die, can choose new materials powder alloy steel, such as V10, ASP23, etc., such materials have high thermal stability and good organization state.

For parts made of Cr12MoV, quenching treatment is carried out after rough machining. There is a large residual stress in the workpiece after quenching, which is easy to lead to cracking during finishing or work. The parts should be tempered while hot after quenching to eliminate the quenching stress. The quenching temperature is controlled at 900-1020℃, and then cooled to 200-220℃ for air cooling, and then quickly returned to 220℃ tempering, this method is called a hardening process, can obtain higher strength and wear resistance, for wear as the main form of failure mold effect is better. In the production of some workpiece with more corners and complex shapes, tempering is not enough to eliminate the quenching stress, and stress relief annealing or multiple aging treatments are needed before finishing to fully release the stress.

For V10, APS23 and other powder alloy steel parts, because they can withstand high temperature tempering, quenching can be used in the secondary hardening process, 1050-1080℃ quenching, and then 490-520℃ high temperature tempering and repeated, can obtain higher impact toughness and stability, for the main failure form of the mold is very suitable. The cost of powder alloy steel is high, but its performance is good, and it is forming a wide application trend.

2 Grinding of parts

There are three main types of machine tools used for grinding: surface grinders, internal and external circular grinders and tool grinders. When finishing grinding, the generation of grinding deformation and grinding cracks should be strictly controlled, even if the crack is very small, it will be revealed in the subsequent processing use. Therefore, the feed of fine grinding should be small, not large, the coolant should be sufficient, and the parts with dimensional tolerances within 0.01mm should be ground at constant temperature as far as possible. It can be seen from the calculation that 300mm long steel, temperature difference of 3℃, the material has a change of 10.8μm, 10.8=1.2×3×3(deformation of 1.2μm/℃ per 100mm), each finishing process should fully consider the influence of this factor.

It is very important to choose the appropriate grinding wheel during fine grinding. For the high vanadium and high molybdenum status of the die steel, GD single crystal corundum grinding wheel is more suitable. When processing cemented carbide and materials with high quenching hardness, diamond grinding wheel with organic binder is preferred. The organic binder grinding wheel has good self-grinding performance and the roughness of the grinding workpiece can reach Ra=0.2μm. With the application of new materials, CBN grinding wheel, also known as cubic borax nitride wheel, shows a very good processing effect, finishing on CNC forming grinding, coordinate grinding machine, CNC internal and external grinding machine, the effect is better than other kinds of grinding wheels. During grinding, pay attention to dressing the grinding wheel in time to keep the sharpness of the grinding wheel. When the grinding wheel is passivated, it will slip and squeeze on the surface of the workpiece, resulting in surface burns and reduced strength.

Most of the processing of plate parts are processed by surface grinding machines, and a long and thin sheet part is often encountered in processing, and the processing of such parts is difficult. Because during processing, under the adsorption of magnetic force, the workpiece deformation, close to the surface of the table, when the workpiece is taken down, the workpiece will have a recovery deformation, the thickness measurement is consistent, but the parallelism can not meet the requirements, the solution can be used magnetic separation grinding method, grinding with equal height block pads under the workpiece, four sides of the block dead, small feed, multi-light knife, after processing a good side, It is no longer necessary to pad equal height blocks and directly adsorb processing, which can improve the grinding effect and achieve the parallelism requirements.

Shaft parts have rotary surfaces, which are widely processed by internal and external cylindrical grinding machines and tool grinding machines. In the processing process, the head frame and the top are equivalent to the bus, if there is a run-out problem, the workpiece processed will also produce this problem, affecting the quality of the parts, so the head frame and the top detection work should be done before processing. When grinding the inner hole, the coolant should be fully poured to the grinding contact position to facilitate the smooth discharge of the grinding. Processing thin-wall shaft parts, it is best to use the clamping process table, clamping force can not be too large, otherwise it is easy to produce “internal triangle” deformation on the circumference of the workpiece.

3. Electric machining control

Modern mold factory, can not lack of electrical machining, electrical machining can be all kinds of special-shaped, high hardness parts for processing, it is divided into two kinds of wire cutting and EDM.

The cutting precision of the slow wire can reach ±0.003mm, and the roughness Ra0.2μm. At the beginning of processing, it is necessary to check the condition of the machine tool first, check the deionization degree of water, water temperature, vertical degree of the silk, tension and other factors to ensure a good processing state. Wire cutting machining is to remove processing on a whole piece of material, it destroys the original stress balance of the workpiece, and it is easy to cause stress concentration, especially at the corner, so when R < 0.2(especially sharp corners), it should be proposed to the design department for improvement. The method of dealing with stress concentration in processing can use the principle of vector translation, leave a margin of about 1mm before finishing, pre-machining a rough shape, and then heat treatment, so that the processing stress is released before finishing to ensure thermal stability.

When processing punch, the choice of cutting position and path of the wire should be carefully considered. The best effect can be obtained by punching and threading. High precision wire cutting processing, usually cutting the number of four times, can ensure the quality of parts. When machining the concave die with taper, in a fast and efficient position, the first rough straight edge, the second taper machining, and then finish the straight edge, so that there is no need to carry out X vertical finishing, only finish the straight edge of the cutting edge section, saving time and cost.

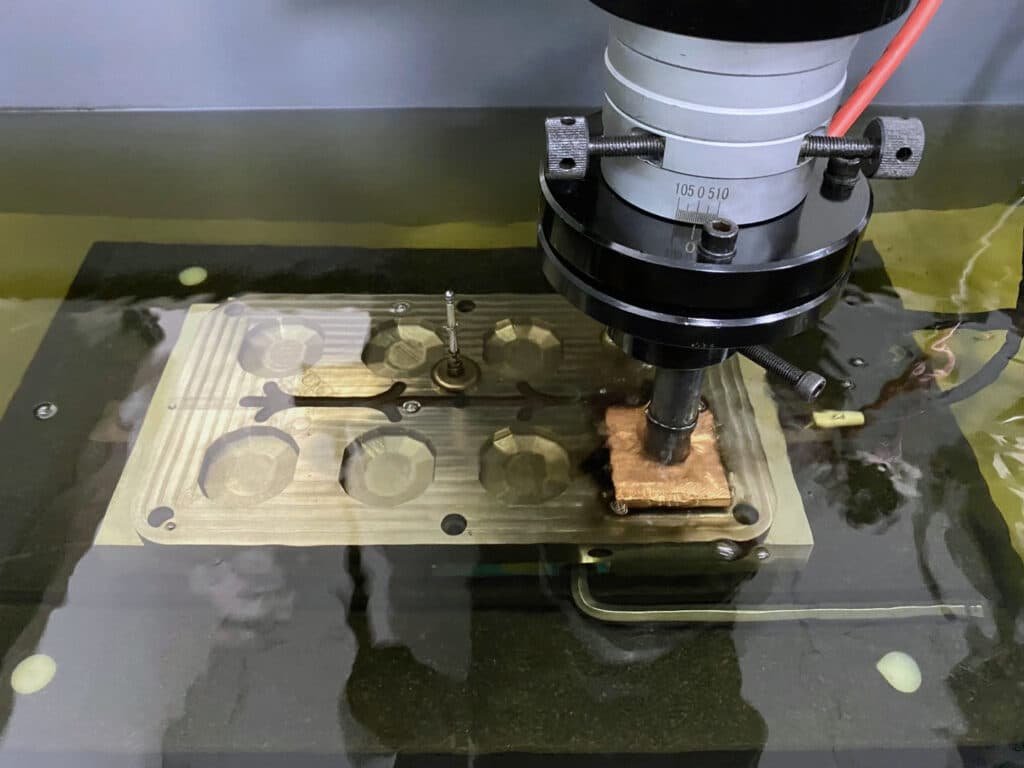

Edm first to make electrodes, electrodes have coarse, fine points. The finishing electrode requires good shape conformity, and it is best to use CNC machine tools to complete the processing. Electrode material selection, copper electrode is mainly used for general steel processing. Cu-W alloy electrode, good overall performance, especially in the process of processing consumption is significantly smaller than copper, with sufficient amount of scouring fluid, very suitable for difficult material processing and cross section shape of complex parts finishing. When making electrodes, it is necessary to calculate the amount of electrode gap and the number of electrodes, when large-area or heavy electrode processing, the workpiece and electrode clamping should be firm to ensure sufficient strength to prevent loose processing. During deep step machining, attention should be paid to the loss of electrodes and the arc discharge caused by poor liquid discharge.

4 Surface treatment and assembly

Parts surface in the processing of the knife marks, wear marks are stress concentration, is the source of crack expansion, so after the end of the processing, the need to strengthen the surface of the parts, through the fitter grinding, processing hidden dangers. Some edges, sharp angles and holes of the workpiece are blunted and R-shaped. In general, the electromachining surface will produce about 6-10μm of metamorphic hardening layer, the color is gray, the hardening layer is brittle and has residual stress, before use to fully eliminate the hardening layer, the method is surface polishing, grinding to remove the hardening layer.

In the process of grinding and electric machining, the workpiece will have a certain magnetization, with weak magnetic force, and it is very easy to absorb some small things, so before assembly, the workpiece should be demagnetized and the surface should be cleaned with ethyl acetate. In the assembly process, first look at the assembly drawing, find all the parts, and then list the equipment order between the parts, list the precautions, and then proceed to assemble the mold, assembly generally install the guide column guide sleeve, and then install the mold frame and convex and concave mold, and then the gap, especially the convex and concave mold gap is adjusted, and the mold inspection is implemented after the assembly is completed. Write an overall situation report. For the problems found, the reverse thinking method can be used, that is, from the post-process to the forward process, from finishing to rough processing, check one by one until the crux is found and the problem is solved.

Practice has proved that good finishing process control can effectively reduce parts out-of-tolerance, scrap, and effectively improve the success rate and service life of the mold.