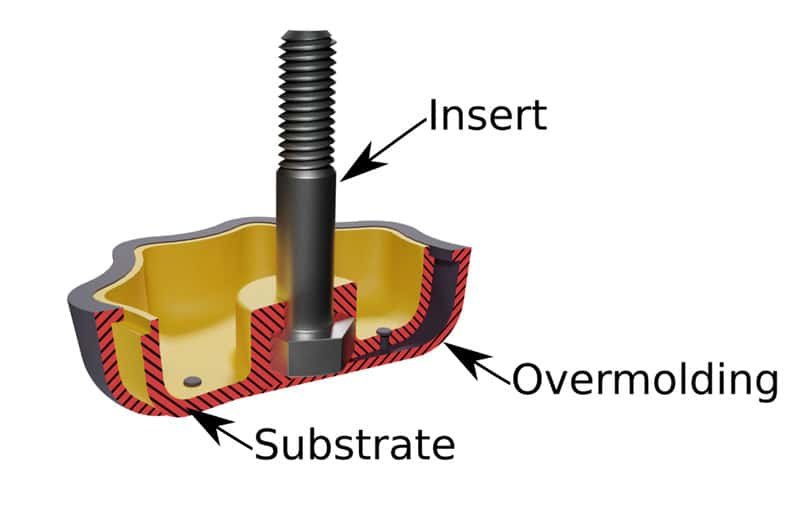

I. Method of Overmolding

In our lives, many products use plastic molds, such as toothbrushes, handles, mice, buttons, car buttons, etc., which are composed of two or more materials. Hard plastic wrapped in soft plastic is rare, while soft plastic wrapped in hard plastic is mostly used for products that come into contact with the hands. Hard plastic wrapped in hard plastic is mostly used for high-precision products.

1. Two-step injection molding

The semi-finished products produced by ordinary injection molding machines are processed and then manually placed into another set of molds for injection molding. The final product is obtained. The equipment requirements can be met by ordinary injection molding machines, so it is also a common practice in factories. It is also known as overmolding.

1) During the second injection molding, the mold needs to be designed with a clamping position and a clearance position for the product to be placed in the designated location more quickly and accurately, avoiding the occurrence of mold pressure.

2) When designing the mold, the product only shrinks the product of the first mold. Because the actual size has been retracted when the product is taken out and placed in the the second mock examination, the the second mock examination will not be shrunk. The dimensional tolerance can only be measured accurately for the first mold, while the dimension of the the second mock examination is usually the product surface with soft rubber appearance, and the dimensional tolerance requirements are not very high.

2. Two-color injection molding machine

Two-color machine assembly involves placing both sets of molds simultaneously onto it or installing soft and hard glue for injection in one go, usually simultaneously injecting both materials during their first trial run. Most two-color machines feature at least two barrels. After injection molding is complete, the rear mold indexing plate rotates 180 degrees for secondary molding to produce desired products.

Two-color molds may consist of one piece or split molds that can be installed onto two-color machines for production, and both methods involve similar principles but differ slightly in mold processing).

Split dual-color mold: Two sets of molds are required, with the same mold frame size for both sets. The rear mold parts are the same, while the front mold parts are different. During installation, it is necessary to ensure that the two sets of molds are at the same height and cannot be offset.

Integrated two-color mold: This mold combines both pouring and ejection systems into one unit, but they must work independently of one another. Thus, its rear part remains similar while its front section features different positioning rings and ejection mechanisms; its advantage being lower processing costs as only one mold needs to be opened, along with less time required for installation of said mold.

1) As opposed to two-step injection molding, single-shot molding does not involve taking out products when switching molds between primary and secondary, enabling two sets of molds to be shrunk in design and adhering to the dimensions tolerance of the first mold.

2) Each factory only has a finite number of two-color molds available, making planning production critical in determining whether any particular machine can meet product molding needs based on dimensions, turntable size and tonnage of two-color machines.

3) Two-color molds have an intuitive product structure and should feature minimal design elements such as an inclined top and slider to ensure safe usage and stability during operation of two-color machines.

4) The guide post of the two-color mold produced by the two-color machine cannot be like the guide post of a normal mold, where the reference angle is offset by 2.00mm towards the center position. Otherwise, during the operation of the two-color machine, the guide post and guide sleeve will collide and fail to close the mold.

Second, the problems that are prone to occur in the molding process of overmolding

1. Dimensional deviation

When injecting hard rubber first and then soft rubber, it is necessary to understand that in mold design, shrinkage should be applied to the hard rubber, while shrinkage should not be applied to the soft rubber. Dimensional deviation is closely related to mold design and part processing; Secondly, the soft rubber part usually has appearance requirements, and the size requirements are not very strict. It is easy to happen that after the first injection, the second injection molding does not meet the requirements in terms of time coordination. At this time, it is necessary to debug the molding parameters and conversion time of the first mold product to correctly obtain the size requirements.

2. Product molding

Two-step injection molding processes are the leading cause of mold damage in factories. When placing semi-finished product from one injection mold into a second one, product may not fit perfectly or shift, leading to damage. Therefore, in cases of low production efficiency and yield it may be beneficial to increase employees’ production awareness or change to two-color molding production as a solution.

3. The package is not on

In order to make the two materials adhere tightly, it is best to use a special two-color mold material, and the smoothness of the mold surface is also a factor. When debugging the product, in addition to debugging the machine to prevent product sticking and material blocking, avoid using release agents at other times.

If the first batch of semi-finished products from a two-step injection molding process are stored for an extended period, prior to being subjected to secondary molding, it is essential to clean away dust from their surfaces and preheat them at 80degC-100degC prior to giving them to secondary molding process to achieve better adhesion and achieve adhesion.

4. The second molding is missing glue

In primary molding, it is necessary to ensure that there is no missing plastic in the product to ensure the improvement of the yield rate during secondary molding. During secondary molding, the soft plastic of TPE material is usually used for encapsulation. Due to the poor fluidity of this material, there are often cases of poor encapsulation and missing edges in the finished product. It is necessary to re-adjust the molding parameters and try to increase the injection time and molding cycle.

5. One-time forming deformation

The temperature and material selection for the secondary molding of the barrel should ensure that the surface melting temperature of the primary molded product is above, with a temperature difference of around 20℃. Secondly, during the secondary molding process, it is recommended to minimize the pressure holding parameters or not use pressure holding, otherwise it is easy to cause dislocation of the joint surface shape or warping deformation of the primary semi-product.

6. Long molding cycle time

It is a common problem in rubber-encapsulated molds, and the main reason for the slow process is that the overall dual-color mold has a higher work efficiency than the split dual-color mold and two-step injection molding.

7. Before the adhesion of the mold

When injection molding TPE soft rubber for secondary molding, the problem of sticking to the front mold is likely to occur. When designing the mold, it is necessary to set a larger draft angle and apply surface etching treatment.

8. The font after being encapsulated is not clear

When we mold a package with a font, there is often a problem with unclear font or logo, mainly due to the low height of the font, which causes great difficulties in process debugging. The standard “pre-press” value should be higher than the theoretical value by 0.02-0.05mm. Only when the product is molded with a clear font can it be used.