Stainless Steel Insert Moulding For Automotive Parts

Switching out metal components for stainless steel insert-molded parts can significantly decrease weight in vehicles and lead to enhanced fuel economy and performance.

YCH Mold:Crafting Precision, Shaping Innovation

- Cost-Effectiveness

- Design Flexibility

- High Efficiency and Productivity

- Consistent Quality and Precision

- Attentive Service

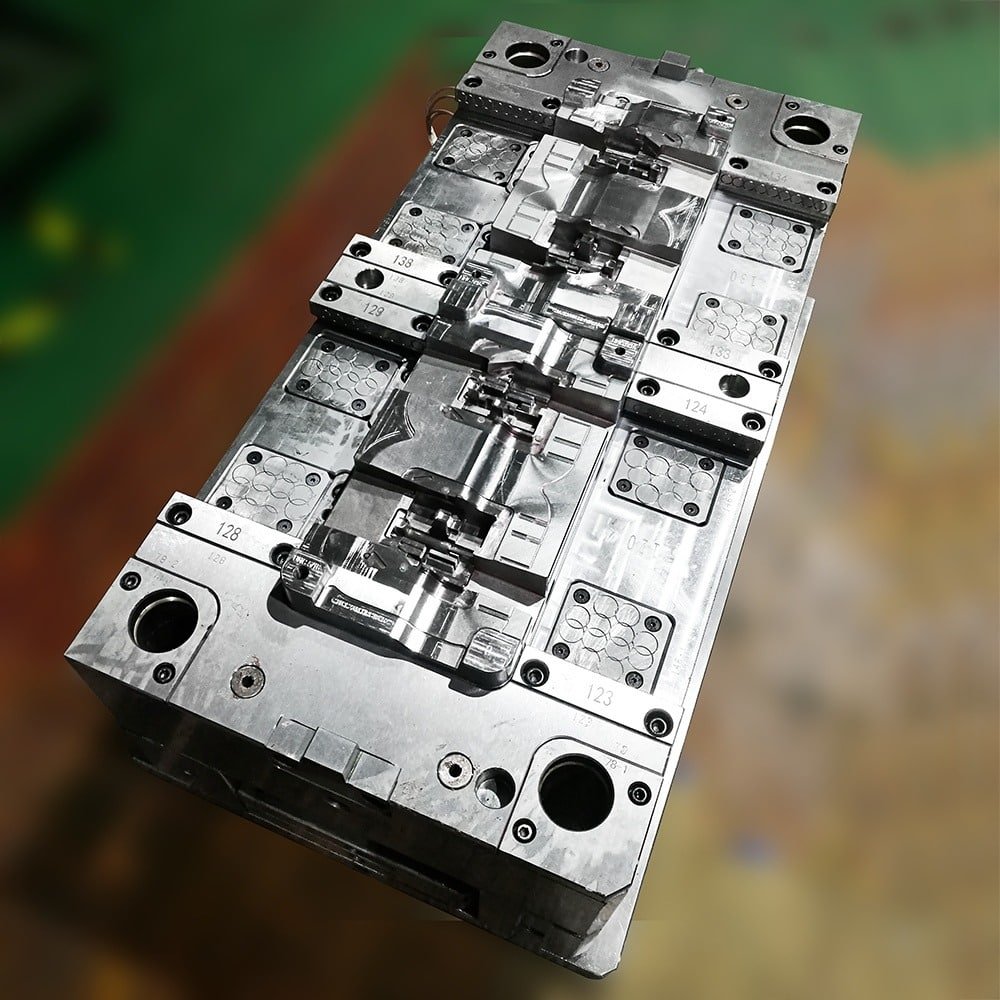

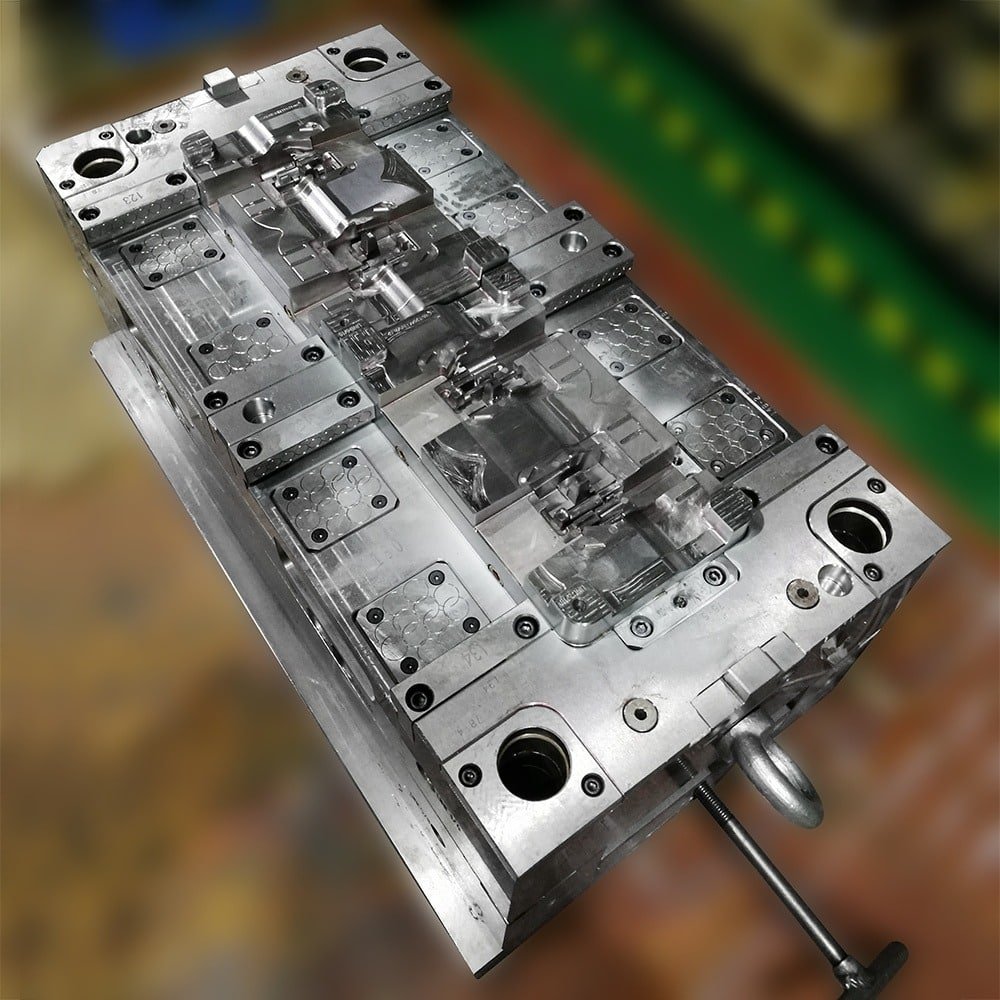

Description

Part function: Plastic component for automotive parts

Part material: PA6+30%GF

Shrink rate: 4/1000

Part finish: MT-11020

Color: Black

Cavity: 1+1 cavity family mold/ multiple cavity mold

Gate type: Synventive hot runner system

Cavity and core steel: 1.2738 (32-38HRC)

Mold base: 1050

Standard components: Hasco standard

Injection molding machine size: 420T

Product Features

Our stainless steel insert molding for automotive parts features are tailored specifically for this industry and include:

1. Corrosion Resistance: Integrating stainless steel inserts into plastic components creates parts with superior corrosion resistance that are well suited to automotive environments subjected to harsh environmental conditions.

2. Increased Strength and Load-Bearing Capability: Including stainless steel inserts can significantly boost mechanical strength and load bearing capabilities for automotive components that experience increased stress or impact, helping ensure their long term reliability and durability.

3. Improved Thermal Stability: Stainless steel inserts can help mitigate temperature variations and thermal cycling effects on molded parts, helping ensure their structural integrity remains in tact over an array of operating temperatures.

4. Tight Tolerances and Precision: Insert molding is capable of producing complex geometries with tight tolerances that integrate stainless steel inserts, providing seamless fit with other automotive components and providing for precise fitment and compatibility with automotive subassemblies.

5. Weight Reduction: Switching out metal components for stainless steel insert-molded parts can significantly decrease weight in vehicles and lead to enhanced fuel economy and performance.

These product features underscore the many advantages associated with stainless steel insert molding for automotive parts, meeting key criteria like durability, corrosion resistance, precision and weight optimization in this market.