Mold temperature refers to the surface temperature of a mold cavity that directly touches a product. It plays an essential role in controlling flowability of plastic melt, cooling rate of product, molding cycle time, crystallization orientation shrinkage of product as well as overall product quality. Mold temperature plays an integral part in product quality.

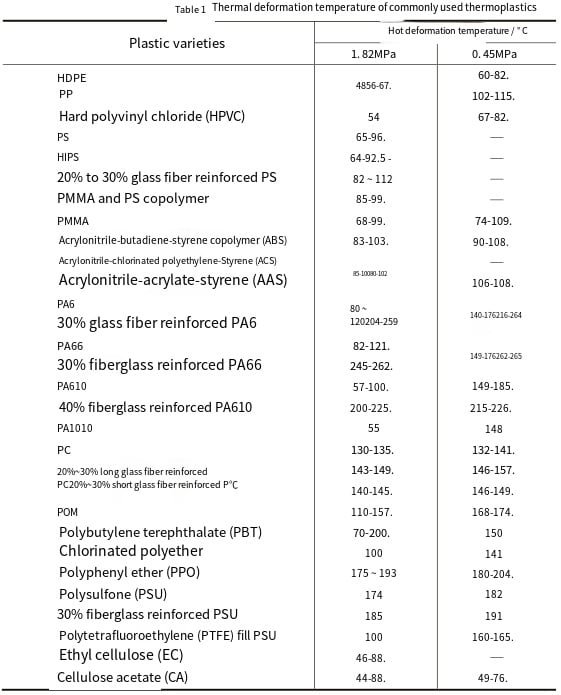

To maintain sufficient stiffness for demoulding without deformation, thermoplastic injection molding requires controlling mold temperature below its thermal deformation temperature or glass transition temperature (Tg) (see Table 1) so as to maintain sufficient thermal deformation temperature or Tg of plastics (as indicated in Table 1). Based on this general principle, specific values for mold temperature must be determined depending on factors like plastic characteristics, usage requirements for products made of thermoplastics and molding process conditions.

Crystalline plastics can be significantly altered by mold temperature. High mold temperatures cause slow cooling rates, fast crystallization rates and increase in hardness/rigidity while lengthening molding cycles/increasing shrinkage rates; low mold temperatures on the other hand show faster cooling rates with slow crystallization rates, reduced crystallinity/improved toughness products molded at fast cooling rates but with slower crystallization rates often leading to late crystallization, leading to post-shrinkage/performance changes changes for certain crystalline plastic products produced when Tg is low – something high mold temperatures cannot always achieve.

Non-crystalline plastics use mold temperature to control viscosity of their melt, or filling rate, and ensure smooth filling. When selecting mold temperatures that support smooth filling rates and shorten the cooling times, low mold temperatures are often best as this improves production efficiency.

Because thick-walled products require longer filling and cooling times, mold temperatures must also be increased accordingly to achieve uniform internal and external cooling and avoid defects caused by large temperature differences between inside and outside (dents and voids) without incurring internal stress caused by internal stresses caused by large temperature differences between inside and outside temperatures (dents and voids). As can be seen from Table 2, PA1010 products have a positive correlation between their thickness and mold temperature; similarly large-area or thin-walled products with high flow resistance also need to maintain high mold temperatures.

| Table 2 Relationship Between The Thickness Of Pa1010 Products And The Mold Temperature | ||||

| wall thickness/mm | <3 | 3-6 | 6-9 | >10 |

| Mold temperature/℃ | 2X0 | 40~60 | 60-90 | 100 |

Plastics with low melt viscosities such as PE, PP, PVC, PS and PA may benefit from low mold temperatures during processing due to their easy flowability and filling requirements. When processing products with higher melt viscosities like PVC, polyphenylene ether or polysulfone however, higher mold temperatures must be used so as to meet filling requirements while also controlling cooling rates for optimal cooling rates in order to prevent defects such as dent and crack defects from appearing.

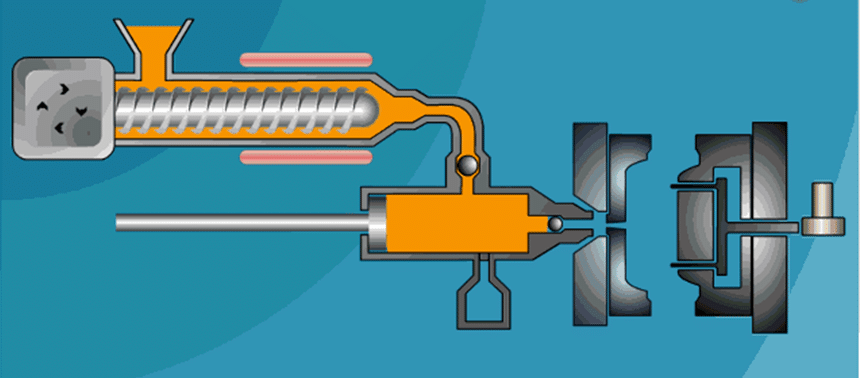

Mold cooling can typically be achieved using either water or oil cooling. When controlling mold temperatures between 5-95degC and 95-120degC, water cooling is preferable, while oil cooling should be utilized between 95-120degC. In certain instances resistance wires and resistance heating rods may also be needed to keep temperatures constant within the mold; see Table 3 for some example plastic barrel, nozzle and mold temperatures as a reference point.

| Table 3: Temperatures of the barrels, nozzles, and molds suitable for some plastics | |||||

| Plastic variety | Cylinder temperature (℃) | Nozzle temperature/C | Mold temperature/‘C | ||

| Posterior segment | Middle section | Front section | |||

| LDPE | 160-170 | 180-190 | 200-220 | 220 to 240 | 20 to 60 |

| HDPE | 200-220 | 220 to 240 | 240 to 280 | 240 to 280 | 30 to 70 |

| PP | 150~210 | 170-230 | 190~250 | 240-250 | 20~65 |

| PS | 140~160 | — | 170-190 | 160-170 | 40-60 |

| ABS | 150780 | 180 to 230 | 210 to 240 | 220-240 | 5()~90 |

| SAN | 170-180 | 210-230 | 200~210 | 180-190 | 40 to 80 |

| SPVC | 125-150 | 140-170 | 160-180 | 150-180 | 15-50 |

| RPVC | 140-160 | 160~180 | 180-200 | 180~200 | 20~60 |

| PCTFE | 250~280 | 270-300 | 290-330 | 340~370 | — |

| PVVA | 150780 | 170-200 | 190-220 | 200-220 | 2()~90 |

| POM | 150-180 | 180-205 | 195~215 | 190-215 | 60-120 |

| PC | 220 to 230 | 240-250 | 260 to 270 | 260 to 270 | 80-100 |

| PA6 | 210 | 220 | 230 | 230 | 40-60 |

| PA66 | 220 | 240 | 250 | 240 | 40 to 80 |

| PUR | 175~20() | 180 to 210 | 205~240 | 205-240 | — |

| CAB | 130-140 | 150-175 | 160-190 | 165-200 | — |

| CA | 130-140 | 150-160 | 165-175 | 165-180 | 40 to 70 |

| CP | 160-190 | 180-210 | 190-220 | 190-220 | — |

| PPO | 260 to 280 | 300-310 | 320-340 | 320 to 340 | 80-130 |

| PSU | 250~270 | 270-290 | 290 to 320 | 300-340 | 100-150 |

| 10 | 90 to 170 | 130~215 | 140~215 | 140 to 220 | — |

| TPX | 240 to 270 | 250 to 280 | 250 to 290 | 250-300 | 20-60 |

| Linear polyester | 70-100 | 70-100 | 70-100 | 70-100 | — |

| alkyd resin | 70 | 70 | 70 | 70 | — |