Selection Techniques for Plastic Mold Materials

Plastic mold materials have different requirements from cold stamping dies in that their working conditions often necessitate operation…

Plastic mold materials have different requirements from cold stamping dies in that their working conditions often necessitate operation…

1. Residual stress of parts Effect of mold and injection molding conditions on residual stress: serial number condition…

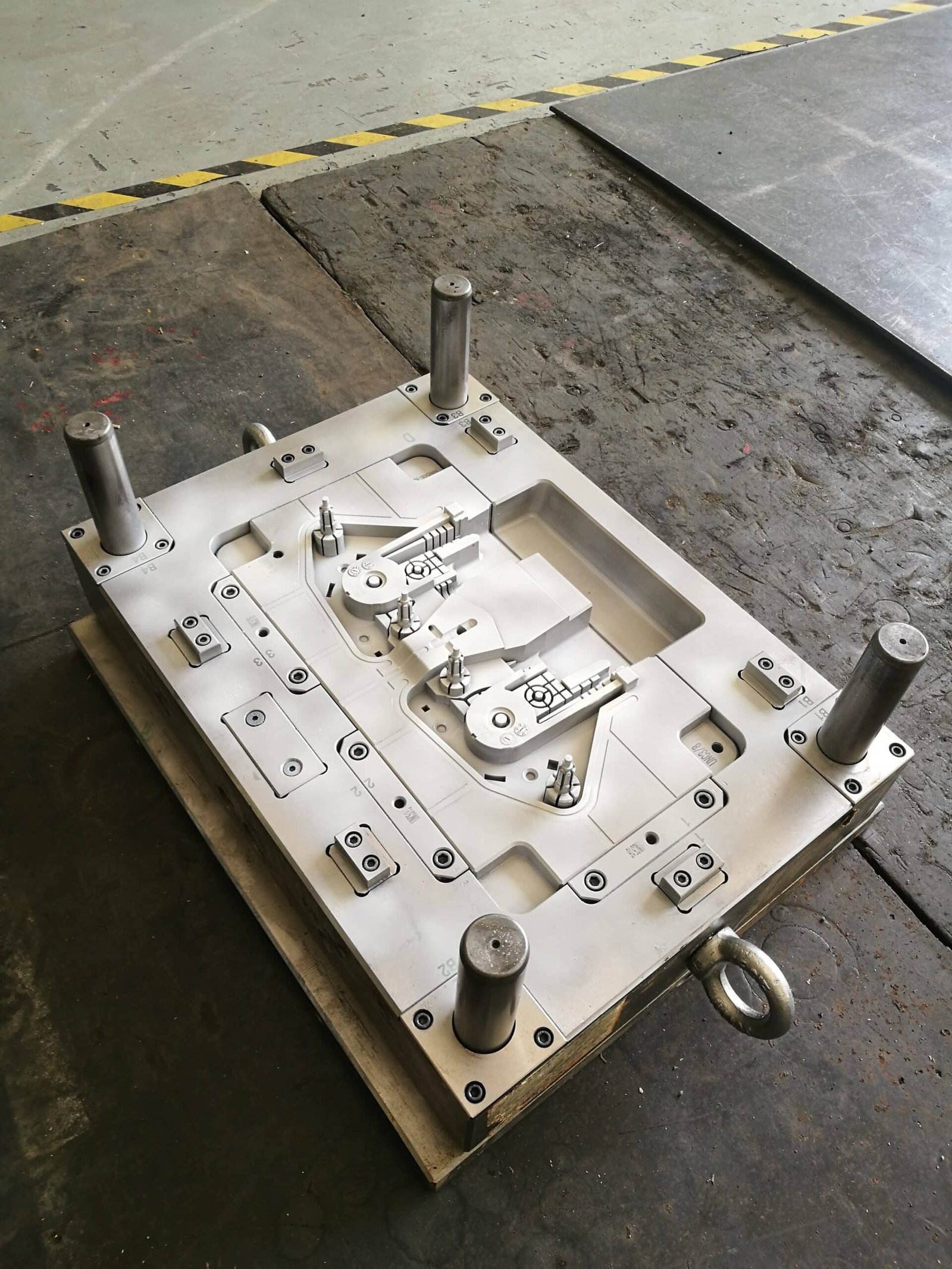

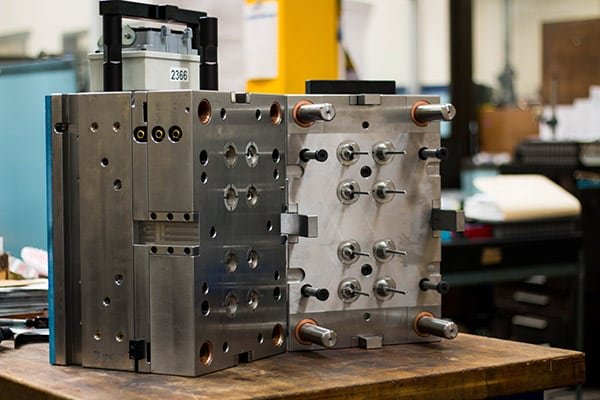

In daily production, the types of molds we use mainly include two plate molds, three plate molds, and…

What is an insert? Insert, a term used in molds, also known as an insert or a sub,…

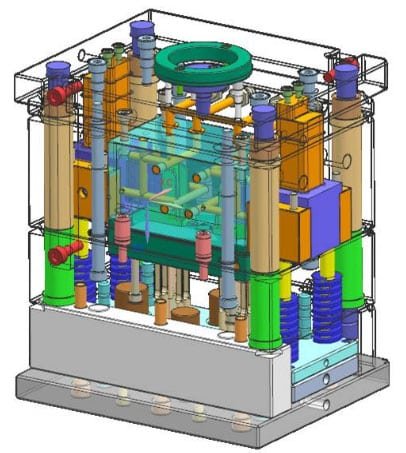

A mold is composed of many parts, the quality of the parts directly affects the quality of the…

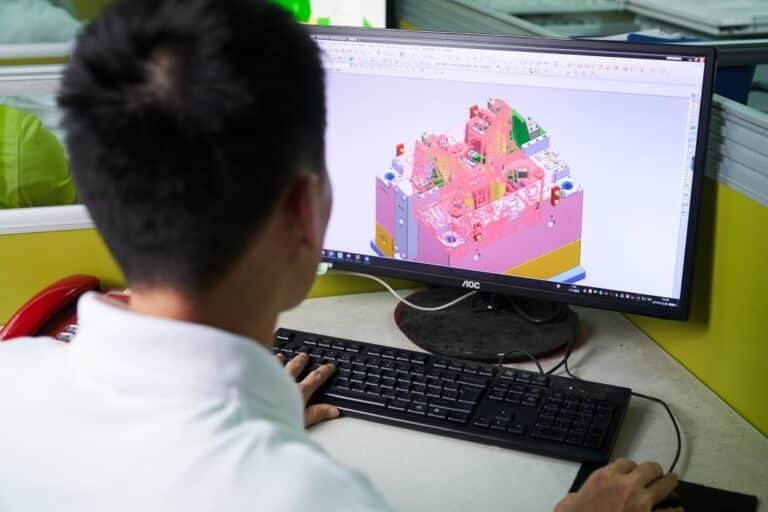

Injection molding is one of the key plastic molding processes. Mold design plays a pivotal role in optimizing…

Overmold (secondary molding): Two plastic materials are not necessarily injected on the same injection molding machine, and are…

Plastic injection mold, more commonly referred to as injection mold, is a production tool capable of mass-producing plastic…

1. Basic principles of two-color mold design: (1) Hard rubber is made once, and soft rubber is made…

1.Gases may form in injection molds. (1) Air trapped between the pouring system and mold cavity.(2) Some raw…

End of content

End of content