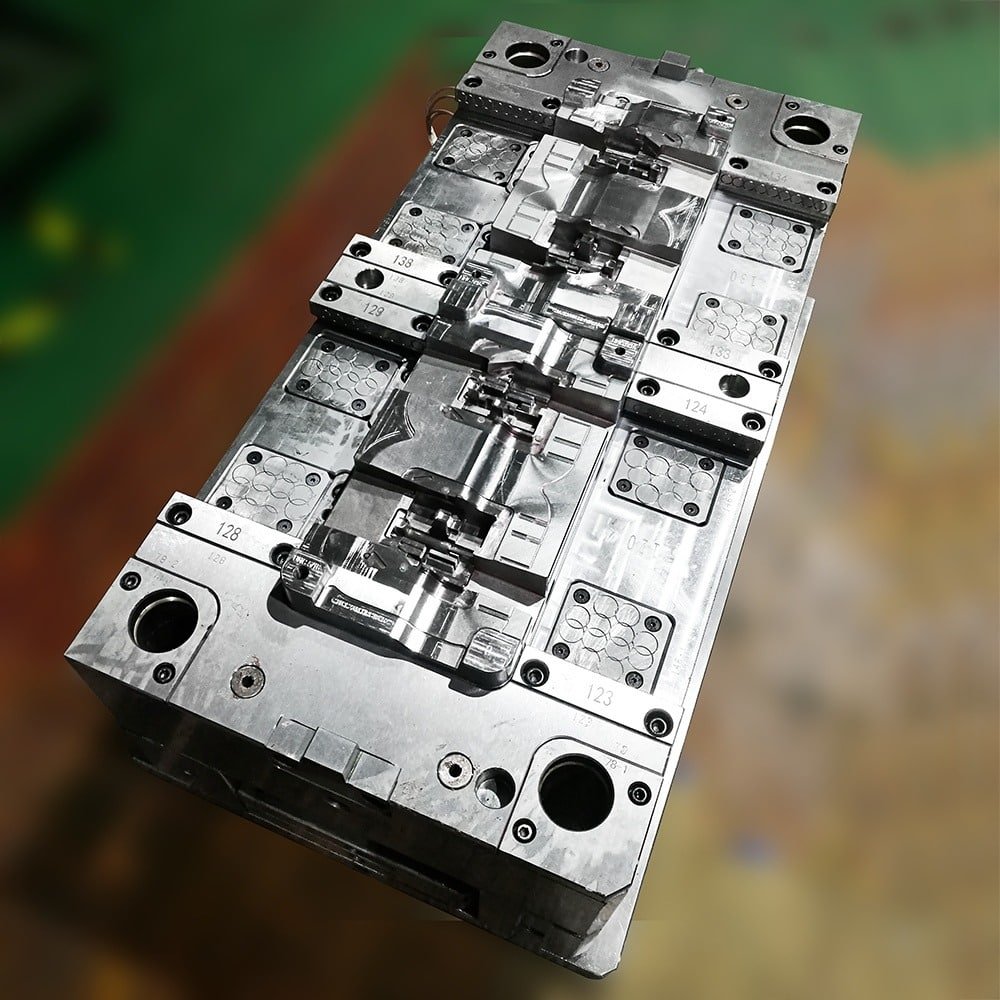

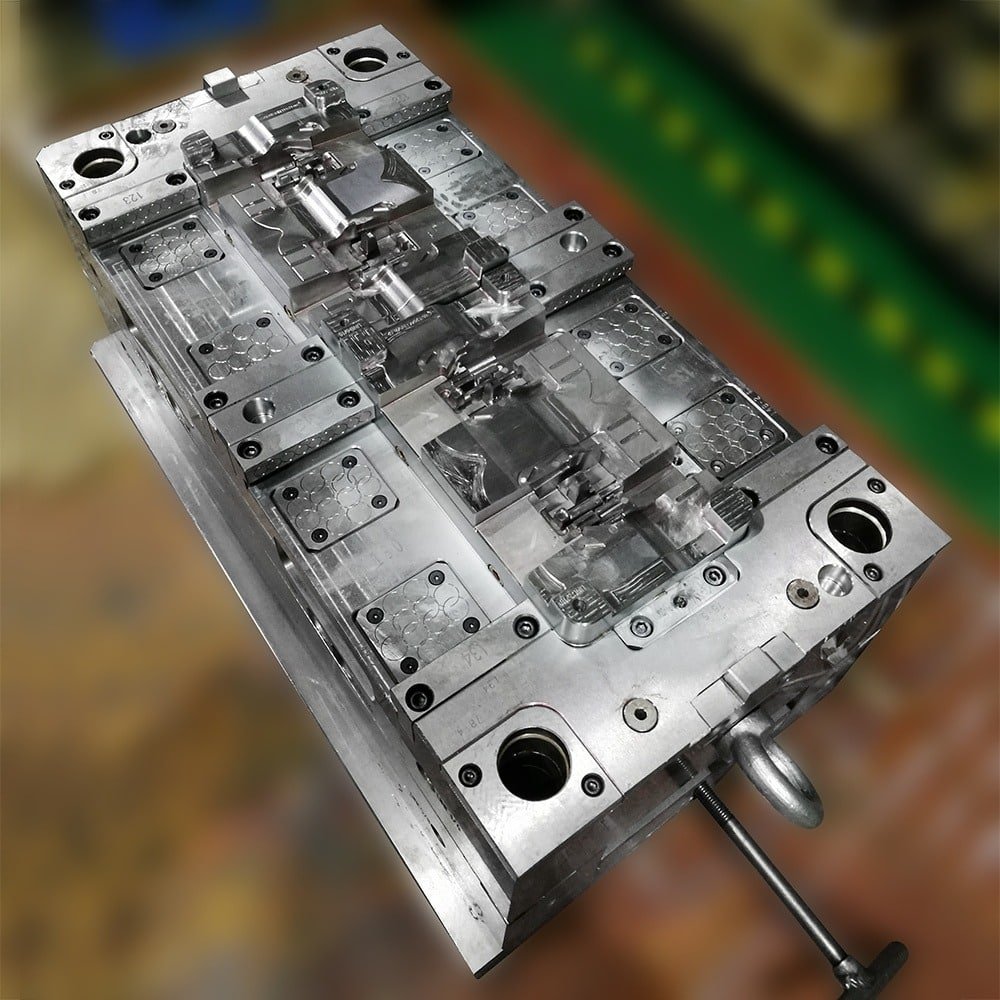

2 Color Injection Molding Components for Automotive Parts

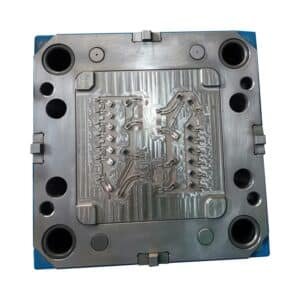

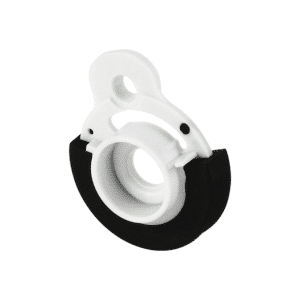

Mold Features:- Key Part for Automotive./ Double Injection Mold/ Two Shot Mould/2K Injection Moulding Technology/ Two Color Mould.

Precision Engineering, Impeccable Quality

Mold Features:- Key Part for Automotive./ Double Injection Mold/ Two Shot Mould/2K Injection Moulding Technology/ Two Color Mould.

Our 2-shot or multi-material molded parts offer many of the desirable characteristics required in industrial equipment applications that prioritize performance, durability and design flexibility.

These features underscore the advantages of employing 2K molds when manufacturing premium-quality audio accessories with improved functionality, durability, and aesthetics.

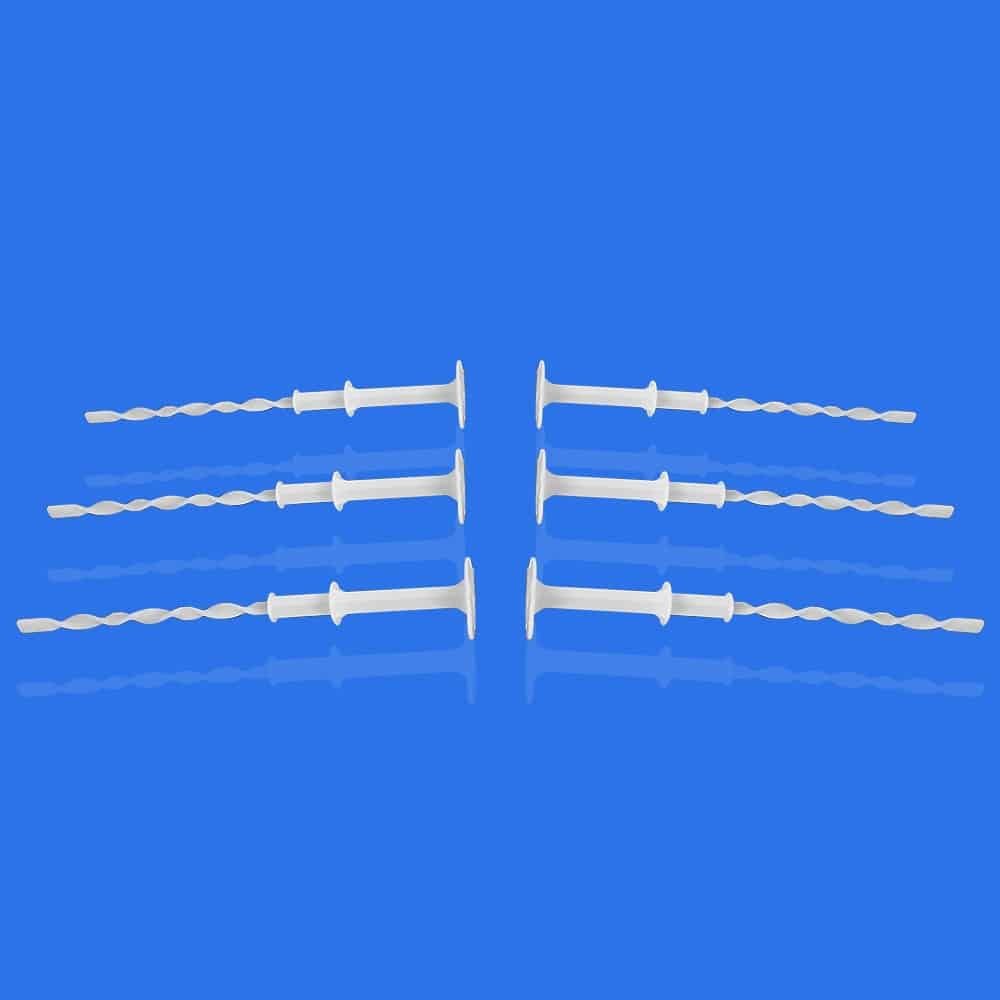

Our brass insert molding can be found in many parts of an automobile’s interior and exterior design as well as electrical connectors – making this material highly flexible in application.

Precision and Consistency: Producing parts with accurate dimensions consistently is critical to ensure high-quality household products.

Our mold is designed and produced according to relevant industry standards and regulations regarding production of packaging materials, guaranteeing product safety, hygiene standards and regulatory compliance in consumer goods applications.

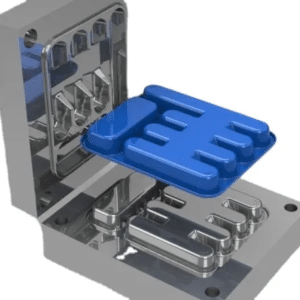

Design Versatility: Combining different materials or colors within one part offers greater design versatility when creating complex and functional components.

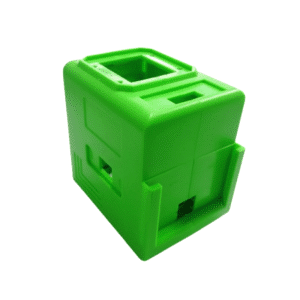

Overall, our customized ABS plastic overmold offers ergonomic design features with safety features for added peace of mind in demanding work environments.

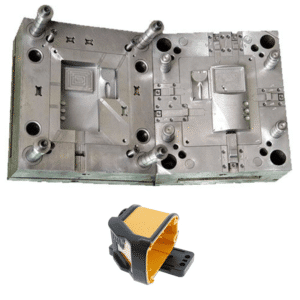

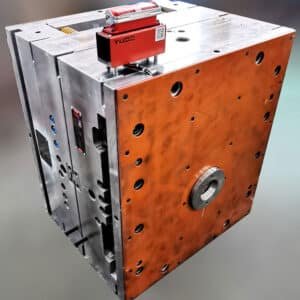

Overall, our custom hot runner injection molds for plastic housing parts offer precision, customization, durability and efficiency – ideal features in applications spanning industries including automotive, electronics and consumer goods.

Consistent Part Quality: Hot runner systems provide effective heat management and balanced filling to achieve consistent part quality, helping minimize defects and variations found in auto spare parts, thus enhancing their overall performance and reliability.

Multi-material injection molding can combine multiple components into a single part, simplifying manufacturing and decreasing any potential points of failure within its finished product.

Features: Double-shot injection molding can be used to bond a part of hard material with another soft material

Overall, our custom plastic injection molded ABS parts for industrial equipment offer durability, precision, chemical resistance and design flexibility that meet the stringent demands of industrial applications.

Cost-Effectiveness: Injection molding can be an economical method of high-volume production, providing economies of scale and optimized material usage.

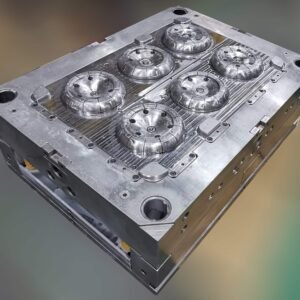

Model NO. YCHOM-2023865921 Plastic Material PC Process Combination Type Single-Process Mode Application Household Appliances, Electronic, Home Use Runner Cold Runner Design Software UG Installation Fixed Certification ISO Standard Lkm Customized Yes Mould Material S316h, Nak80, 718h Hardness 45-56 HRC Parts Material ABS, PC, PA66, PP, TPU, etc. Mould Life 500K~1000K Shots Item Plastic Injection Mould…

Quality Control Measures: Adherence to rigorous quality assurance practices throughout the manufacturing process is imperative in guaranteeing both reliability and safety for electrical parts.

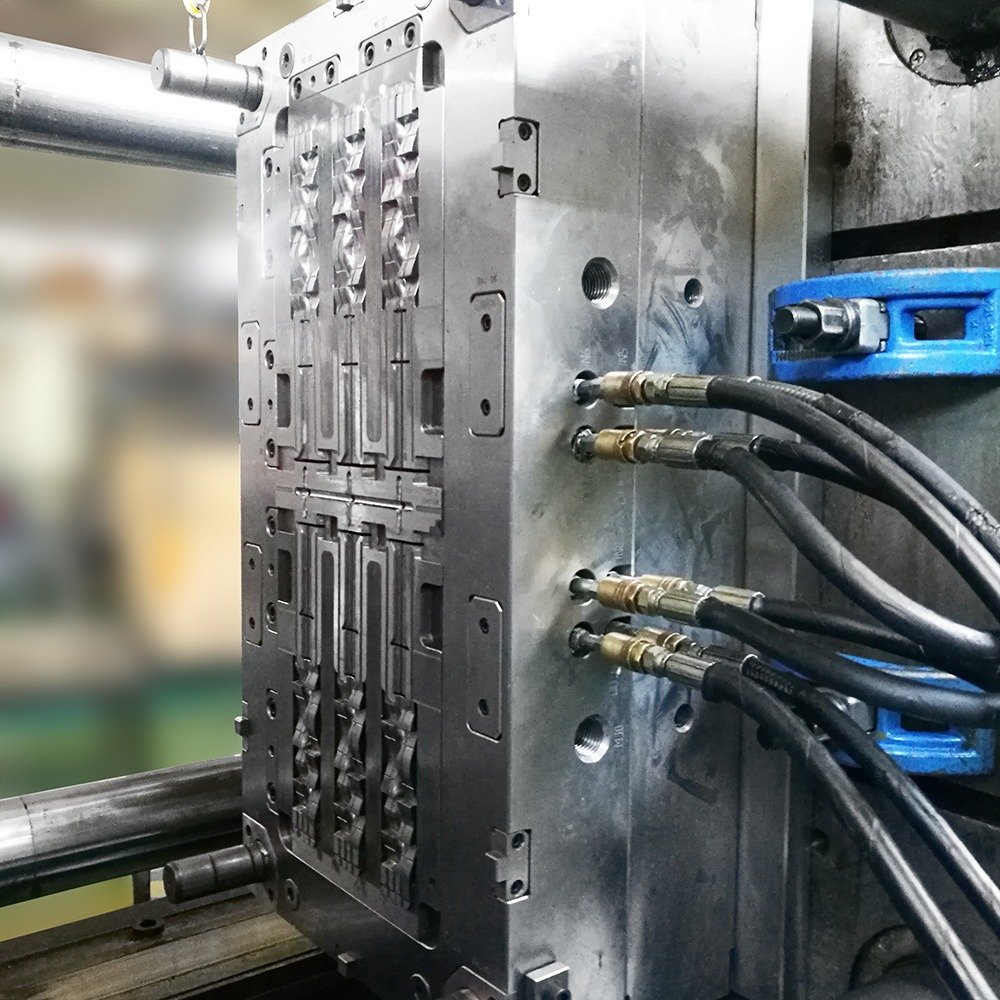

High-grade materials and precise machining ensure multi-cavity molds’ longevity and operational lifespan are maximized, giving their users peace of mind during use.

Customizable options to meet specific automotive industry specifications; long-term durability and reliability are features to consider for long-term use.

Overall, Our Hot Runner Plastic Injection Mold for Industrial Equipment delivers precision control, reduced waste, faster cycle times and the ability to mold complex designs with precision

These product characteristics emphasize the advantages of employing metal insert injection molding for plastic parts in automotive industry applications, meeting critical requirements such as strength, weight optimization, resilience, precision and ease of integration.

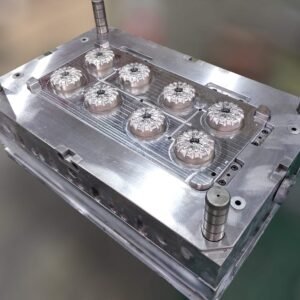

When do we need multiple cavities? Before starting to make plastic molds, plastic mold suppliers need to understand the following customer’s needs to facilitate design.

High Precision: The mould ensures accurate and consistent production of caps while meeting tight tolerances to achieve uniformity across all cavities.

Mold features:

Mold features:

Precision Overmolding:Ensure precise overmolding to seamlessly integrate different materials, like rubber or TPE, for enhanced grip and shock absorption.

Part function: Plastic component for industrial equipment Part material: PA66+30%GF Shrink rate: 5/1000 Part finish: MT-11030 Color: Black Cavity: 1 cavity/ single cavity Gate type: Incoe hot runner system Cavity and core steel: H13 (48-52HRC) Mold base: 1050 Standard components: Hasco standard Injection molding machine size: 320T

These features demonstrate how plastic overmolding for automotive parts addresses critical criteria such as aesthetics, functionality, comfort, durability and simplified assembly in the industry.

End of content

End of content